About UNIASEN

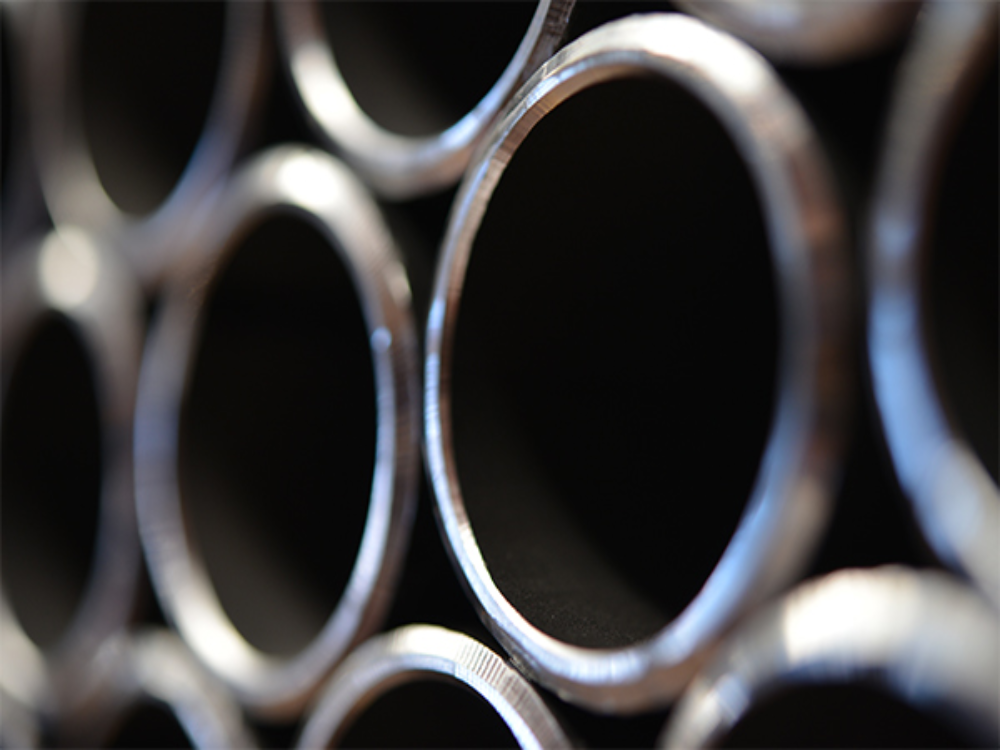

UniAsen (Tianjin) Co., Ltd. is the most professional carbon steel pipe manufacturer, supplier and exporter in China. We are mainly engaged in the production and sales of various types of steel pipes and related products.

The products mainly involve ERW pipe, SSAW pipe, LSAW pipe, SMLS pipe, Line pipe, sprinkler pipe, shoulder pipes, Octg, Pipe Fittings, etc. These pipes have broad application prospects in petroleum, chemical industry, construction, water conservancy, coal and other fields. View project examples.

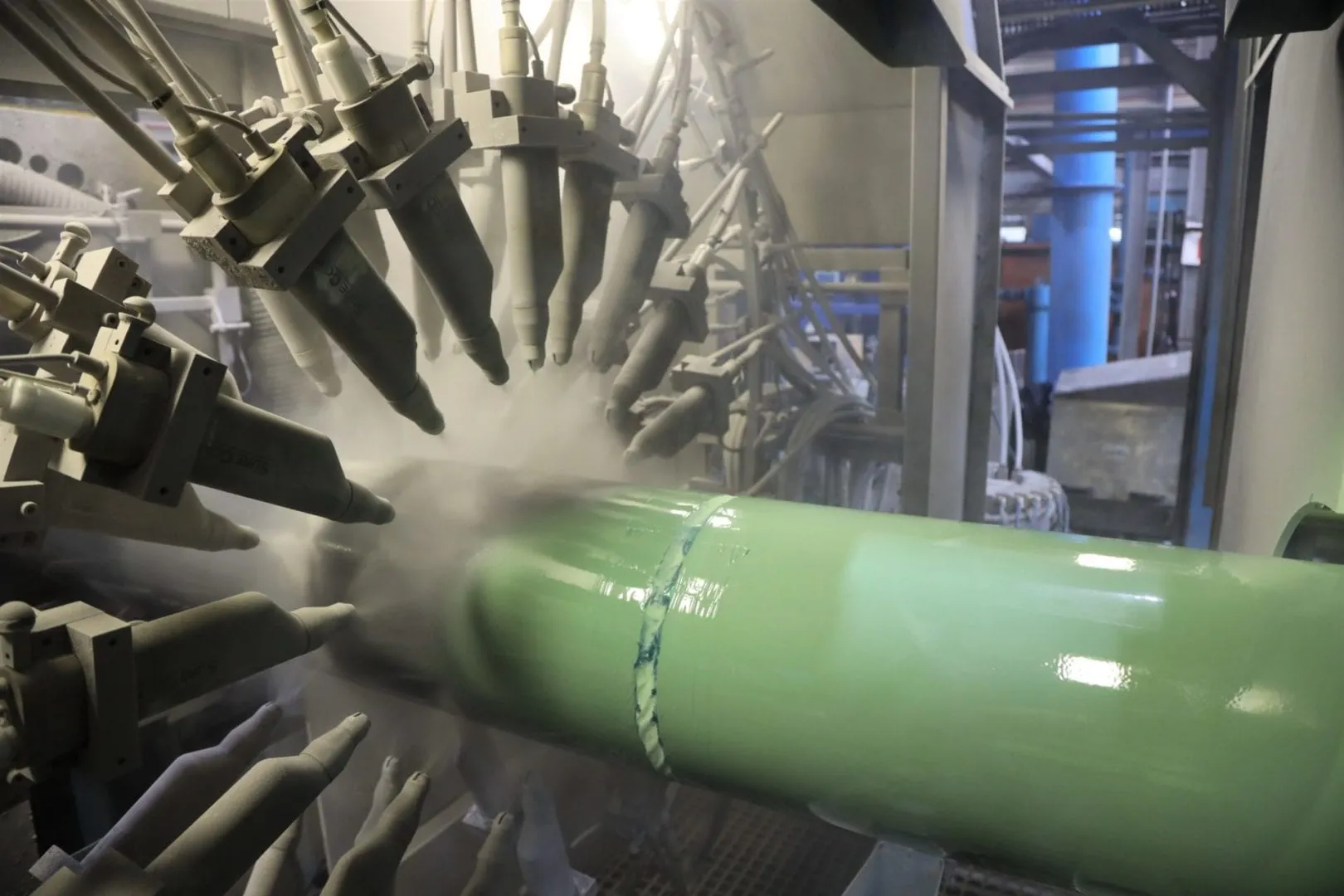

As a carbon steel pipe supplier, UNIASEN now has a number of modern production lines, including an advanced automated steel pipe welding line and heat treatment line, with about 20,000 tons of carbon steel pipe.

We have more than 20 pipe specialists who will provide expert advice on your products and help you complete your project faster and better!

26

Years Experience

279

Project Done

235

Employee

1292

Happy Clients

Why Choose US

Superior Quality

Carbon steel pipes are manufactured in strict compliance with international standards. Our pipes comply with more than 50 international standards, including API 5L, ASTM A53, EN10219, and others.

Rich Experience

We have been serving oil and gas companies for more than 20 years. So far, we have in-depth cooperation with more than 1,000 well-known companies.

Diversified Product Lines

To meet the diverse needs of the market. Uniasen provides carbon steel pipes for different purposes. The types and manufacturing processes of different carbon steel pipes can be viewed.

On-Time Delivery

We have more than 20,000 tons of pipe products in stock, and we can deliver the products in stock to the port of shipment within 7 days.

Our Services and Projects

China Carbon Steel Pipe Exporter

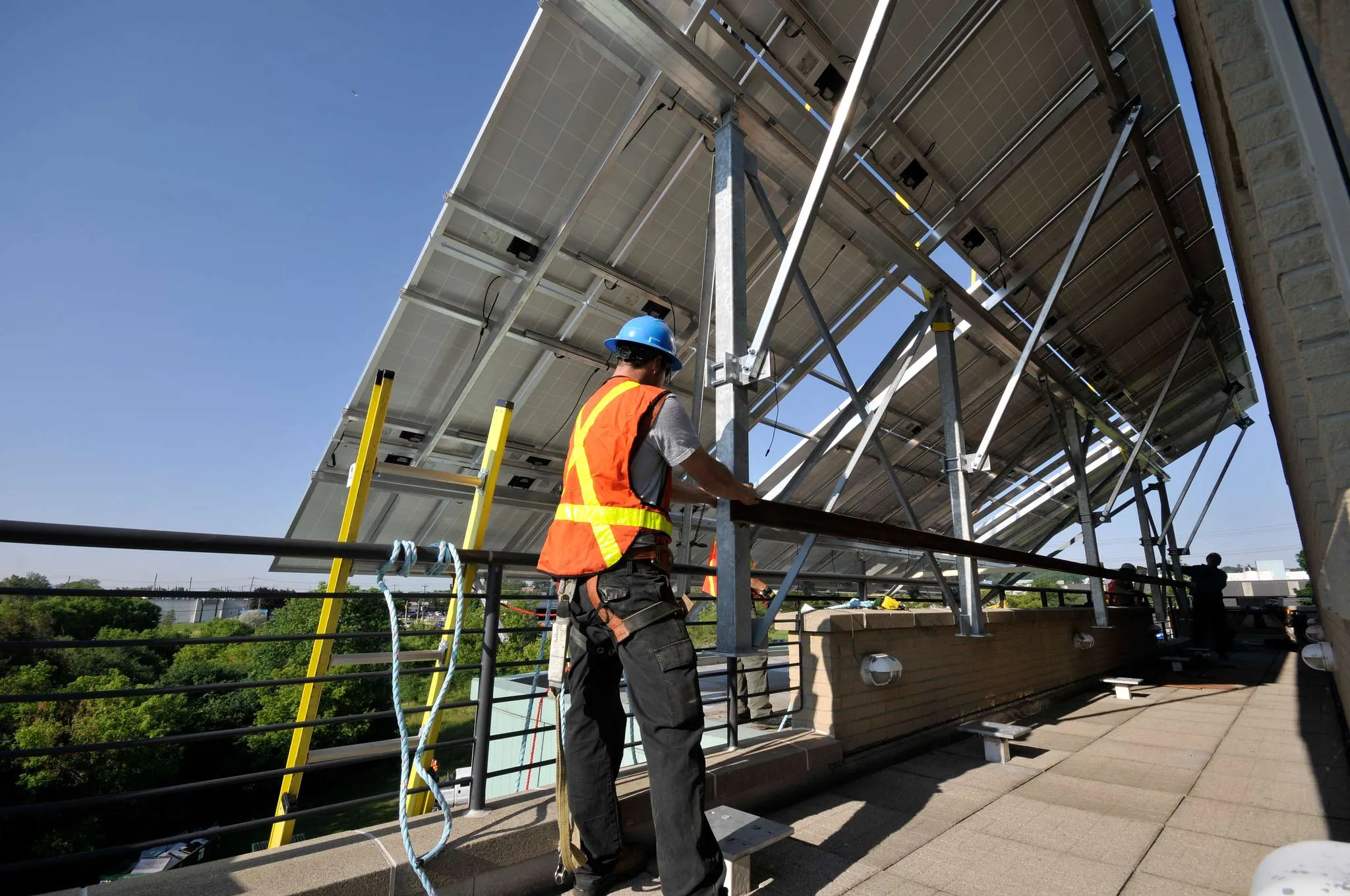

UNIASEN has 17 years of rich experience in carbon steel pipe manufacturing. The products have been widely used in many industries worldwide, such as oil & gas, solar, water transmission, construction, etc.

- High-quality carbon steel tubes and pipes, strict production process.

- With an extensive product range, steel pipes are suitable for various industries.

- Customized solutions and tailor-made carbon steel pipes.

- Advanced production equipment and technology, efficient production.

- Professional team, providing professional technical support.

Recent News