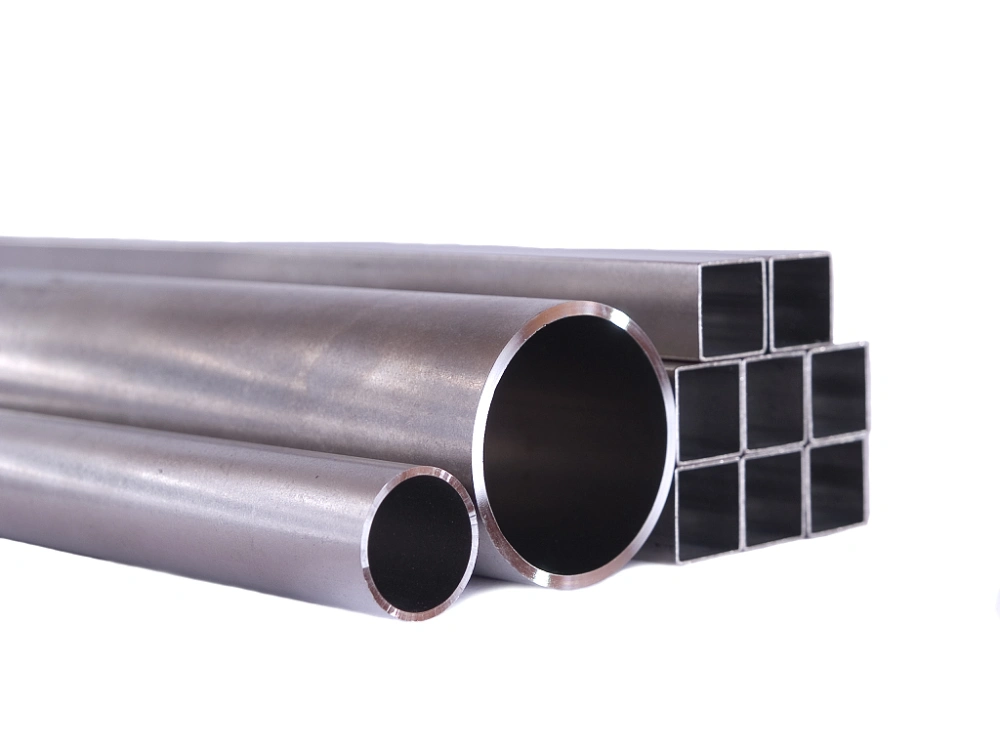

Hollow Section

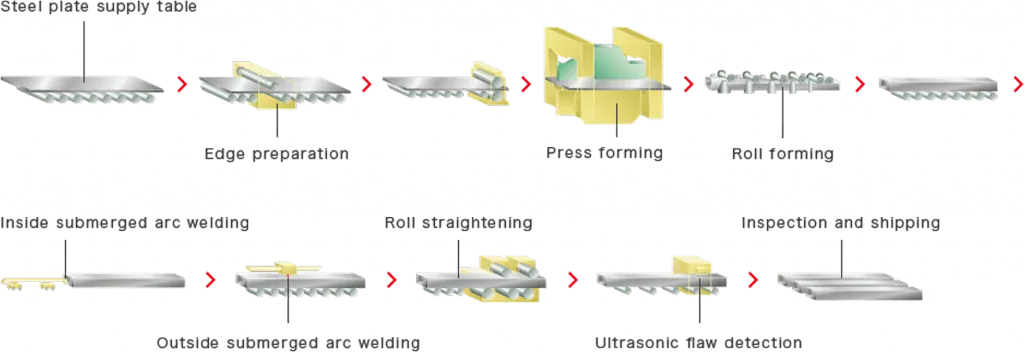

“Hollow Section” (HSS: Hollow Structural Section) refers to a steel tube or profile with a hollow section, usually made of steel. This welded steel tube can be round, square, rectangular or other cross-sections, with high strength, excellent rigidity, outstanding corrosion resistance and other characteristics.

HSS profiles meet many international standard specifications, including ASTM A500, A1085 and A1065. This type of tube or profile is commonly used in various engineering and construction projects. For example, it is used for components or structures made of metal, plastic, concrete, etc.