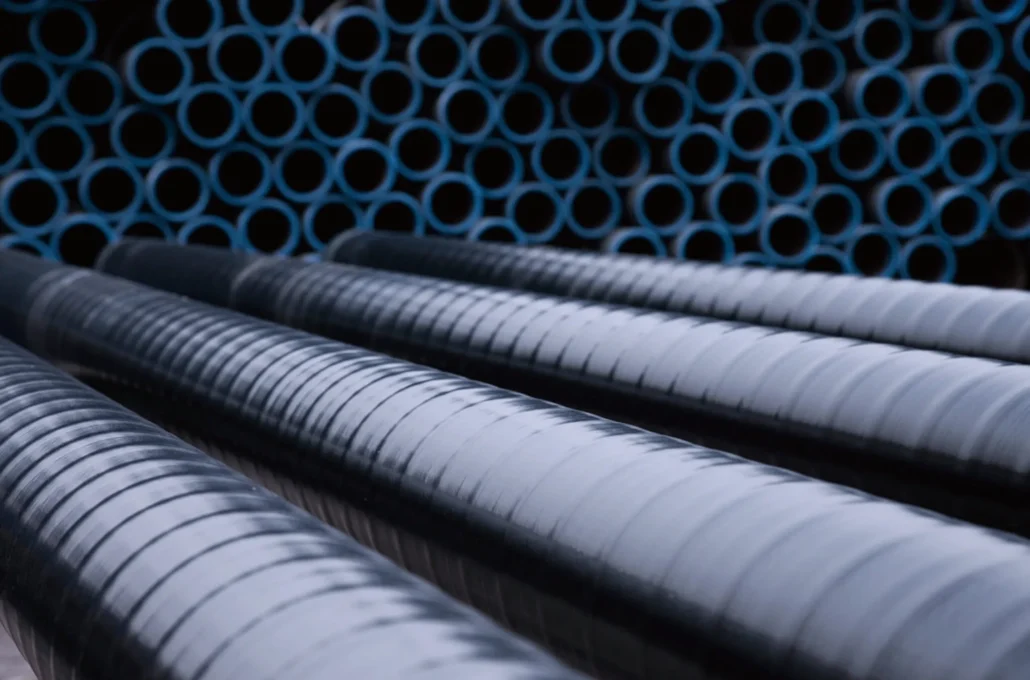

What is API 5L?

API 5L is a standard for steel pipes that are designed for transporting oil and gas. These pipes are made from carbon steel and are available in two different types: seamless and welded (including ERW and SAW). The materials used for these pipes include grades such as B, X42, X46, X52, X56, X60, X65, X70, and X80, which are suitable for use in onshore, offshore, and sour services. This standard outlines the specifications for line pipes and is used to implement steel pipes in pipeline transportation systems.

API 5L Pipe Standard Scope

The API 5L Pipe Standard outlines the manufacturing requirements for seamless and welded steel pipes used in petroleum and natural gas industries for pipeline transportation systems. The scope is defined in the 46th Edition of API SPEC 5L and includes two product specification levels (PSL1 and PSL2). It is important to note that this standard does not apply to cast pipe. Essentially, the API 5L pipe is a carbon steel pipe utilized for oil and gas transmission systems. Additionally, other fluids such as steam, water, and slurry may also use the API 5L standard for transmission purposes.

Different Manufacturing Types for API 5L Pipes

The API 5L specification is an essential guideline that dictates the manufacturing types for pipes used in the oil and gas industry. This section will explore the different manufacturing types available for API 5L pipes, focusing on two categories: welded and seamless. Each category has specific manufacturing methods that create different types of pipes.

Welded Pipes

Welded pipes are manufactured by joining two metal sheets or sections along their edges. There are several types of welded pipes, including ERW, SAW, DSAW, LSAW, SSAW, and HSAW.

-

ERW Pipes

Electric Resistance Welded (ERW) pipes are created using an electrical current that heats the edges of the pipe material, causing them to fuse together. This method is typically used for pipes with a diameter of 24 inches or smaller.

-

LSAW Pipes

The LSAW process involves bending and welding steel plates along their length to create a pipe. This method, also known as the JCOE manufacturing process, is used for larger diameter pipes up to 84 inches, providing a strong and durable final product.

-

SSAW/HSAW Pipes

Spiral Submerged Arc Welded (SSAW) and Helical Submerged Arc Welded (HSAW) pipes are manufactured by winding a steel strip into a helical shape and then welding the edges together. These pipes can have diameters of up to 84 inches.

Seamless Pipes

Seamless pipes are made without any welded joints, providing a uniform structure throughout the pipe. They are typically used for small diameter pipes, usually under 24 inches. There are two types of seamless pipes: hot rolled and cold rolled.

-

Hot-Rolled Seamless Pipes

Hot-rolled seamless pipes are created by heating a metal billet and then forcing it through a series of rollers to create a pipe shape. This method is used for seamless pipes with diameters greater than 20 inches.

-

Cold-Rolled Seamless Pipes

Cold-rolled seamless pipes are manufactured by rolling a metal billet at room temperature through a series of rollers to achieve the desired pipe shape. This process is typically used for small-diameter pipes.

Manufacturing Processes of API 5L Steel Pipes

Each manufacturing type mentioned above has a unique process that contributes to the final product’s characteristics and performance.

ERW Process

The ERW process involves passing a current through the edges of the metal sections to generate heat, which then melts and fuses the edges together, forming a welded joint. This process is quick, efficient, and suitable for smaller-diameter pipes.

LSAW Process

The LSAW process involves bending and welding steel plates along their length to create a pipe. This method, also known as the JCOE manufacturing process, is used for larger-diameter pipes up to 84 inches, providing a strong and durable final product.

SSAW/HSAW Process

SSAW and HSAW processes involve winding a steel strip into a helical shape and then welding the edges together. This method is suitable for creating pipes with diameters of up to 84 inches, providing a versatile and cost-effective option for various applications.

Hot and Cold Rolled Seamless Process

Hot-rolled seamless pipes are made by heating a metal billet and then forcing it through a series of rollers to create the desired pipe shape. Cold-rolled seamless pipes, on the other hand, are created by rolling a metal billet at room temperature through a series of rollers. Both processes result in seamless pipes that offer uniform structure and strength, ideal for smaller-diameter pipes.