china spiral welded pipe manufacturer and supplier

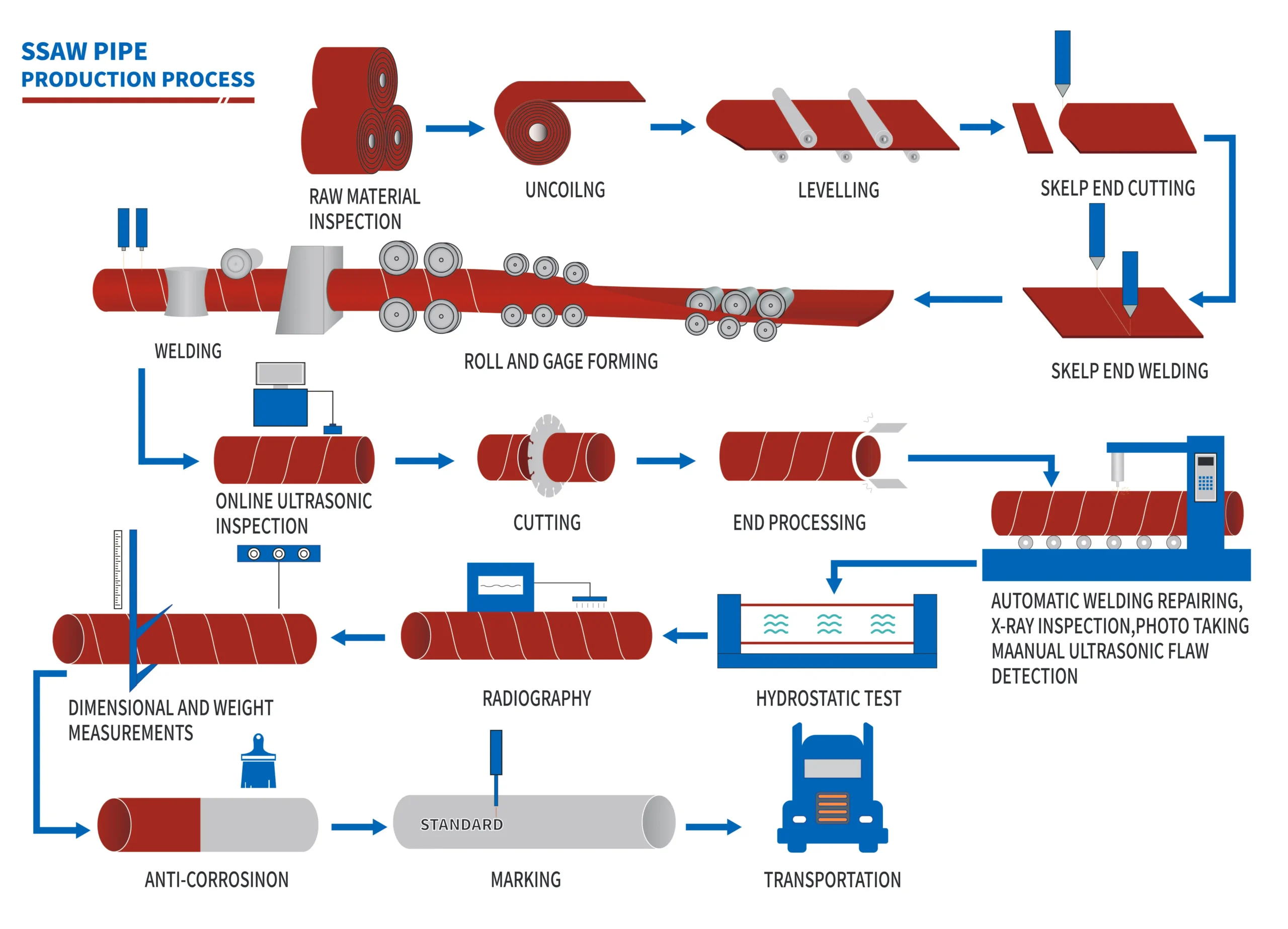

SSAW (Spiral Submerged Arc Welded) Steel Pipes, also known as spiral welded pipes, are produced through a continuous spiral welding process using hot-rolled steel coils, followed by submerged arc welding for superior weld quality.

These pipes, often exceeding 20 inches in nominal pipe size (NPS), are highly customizable, supporting large diameters and extended lengths to meet diverse project needs.

SSAW pipes can handle high pressure and tension. They work well for transporting liquids, gases, and fluids. These pipes are used in municipal water and wastewater systems, oil and gas, petrochemical, and urban construction.

Request A Free Quote