With the rapid development of the industry and construction industry. Pipelines are keeping up with the pace and becoming more diversified.

As a result, there are more pipe manufacturing methods, among which the most discussed in the industry is the difference between seamless steel pipes and electric welded pipes.

Which pipeline is better? We’ll take a closer look at the differences between the two below. This will help you understand when to choose which type of steel pipe to best meet your specific needs.

- Basic Concepts

- Manufacturing Process

- Pros And Cons.

- Application

- Cost

Seamless vs. Welded Steel Pipe

Basic Concepts

Before understanding the difference between seamless steel pipe and welded steel pipe. Let us first have a deep understanding of the basic concepts and working principles of these two types of steel pipes.

Seamless steel pipe

- Manufacturing method: Seamless steel tubes are produced by heating and rolling from a single round billet. This blank is passed through a hollow mold at high temperature to form a seamless tube. Therefore, the seamless steel pipe does not have any welded joints on the surface.

- Features: Due to the continuity of the manufacturing process. The seamless steel pipe has a very uniform internal structure without internal or external welds. This endows seamless steel pipe with excellent compression and corrosion resistance.

- Fields of application: Seamless steel pipes are often used in applications requiring high strength, high corrosion resistance, and high pressure. Such as oil and gas transmission, chemical engineering, and nuclear energy.

Welded steel pipe

- Manufacturing method: Welded steel pipe is formed by heating the edges of two or more steel plates or strips until they melt, and then welding them together to form a pipe. This process can use different welding methods including resistance welding, high frequency welding, etc.

- Features: Welded steel pipes have welded seams along their length, which are the result of welded edges. This makes its internal structure slightly uneven at the seams, but still strong enough for most applications.

- Fields of application: Welded steel pipes are usually used in low pressure or general purposes, such as building structures, plumbing pipes, general engineering and light industry.

Manufacturing Process Comparison

SMLS Pipe Manufacturing Process

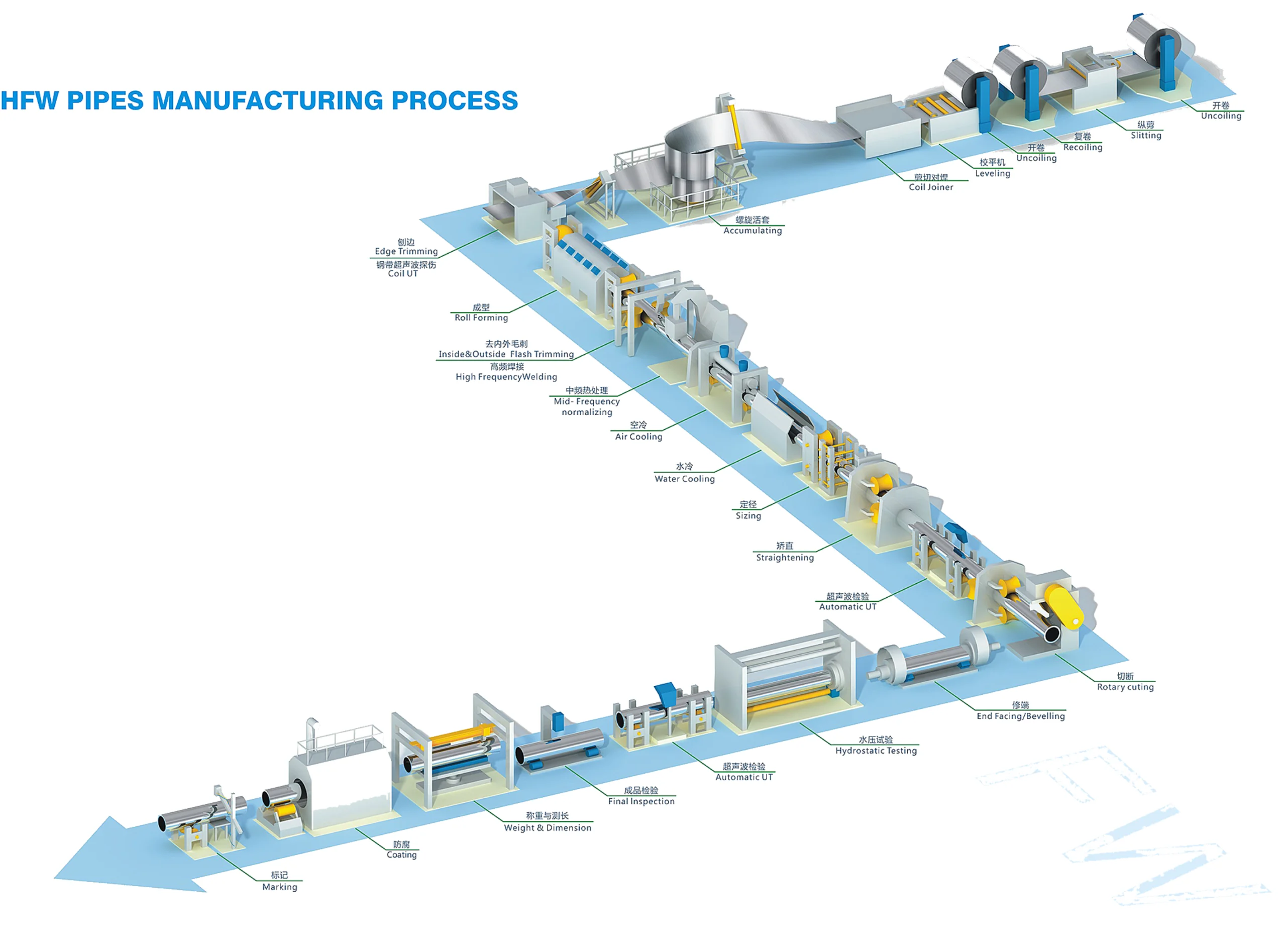

Welded Steel Pipe Manufacturing Process

The manufacturing process of seamless steel pipes is more complicated, requiring high-quality blanks and precise workmanship.

The manufacturing process of welded steel pipe is more cost-effective and suitable for high-volume production.

Seamless steel pipe has a more uniform internal structure and no welded seams, so it excels in high-pressure and high-temperature applications.

Welded steel pipe has welded seams but is still strong enough for many general purpose low pressure applications.

The difference in the manufacturing process directly affects the performance of the steel pipe and the selection of the application field. so the specific requirements of the project need to be considered when making the selection.

Performance Comparison

| Seamless Steel Pipe | Welded Steel Pipe | |

|---|---|---|

| Strength | Higher strength | Low intensity |

| Corrosion resistance | Less susceptible to corrosion | Susceptible to corrosion |

| Pressure Capability | Ability to withstand | Low pressure resistance |

Seamless steel pipe is generally superior to welded steel pipe. This terms of strength, corrosion resistance, and pressure resistance. And is suitable for high-pressure, high-temperature, corrosion-resistant applications that require high performance.

Welded steel pipe excels in cost-effectiveness and suitability for general-purpose, low-pressure applications.

Applicable field

Seamless steel pipes and welded steel pipes play their respective advantages in different application fields. And the specific choice depends on the needs and performance requirements of the project. The following is the application of seamless steel pipes and welded steel pipes:

Application fields of seamless steel pipe

- Oil and Gas Transmission: Seamless steel pipes are commonly used in oil and gas transmission pipelines. Because they can withstand high pressure and high temperature conditions without the weak points of welded joints.

- Chemical Engineering: In chemical engineering, the corrosion resistance and high strength of seamless steel tubes make them ideal for handling corrosive chemicals.

- Nuclear energy industry: Nuclear energy facilities require highly reliable materials, and seamless steel pipes are often selected for their uniform internal structure and high pressure resistance.

Fields of application of welded steel pipes

- Construction and Structures: Welded steel pipes are widely used in construction and structural fields, such as stairs, handrails, bridges and building support structures as they provide cost-effective solutions.

- Plumbing and water supply piping: In low pressure plumbing and water supply piping, welded steel pipes are often preferred as they fulfill basic plumbing needs.

- General Engineering: For general engineering projects such as manufacturing, light industrial, and general piping applications, welded steel pipe offers an affordable option.

Cost Comparison

| Seamless Steel Pipe | Welded Steel Pipe | |

|---|---|---|

| Manufacturing cost | Higher cost | Lower cost |

| Raw materials | Raw materials are expensive | Low cost of raw materials |

| Production time | Long production time | Fast production |

Seamless steel pipes generally have high manufacturing costs and raw material costs. But are superior in high performance, high pressure, high temperature and corrosion resistance.

Welded steel pipe generally has lower manufacturing and raw material costs. It is suitable for general purpose, low pressure, and less economical applications.

Choose the steel pipe you need. Tell UNIASEN steel pipe manufacturer your budget and requirements. We will help you calculate the specific price in detail.

The final selection should be based on the specific needs of the project, performance requirements, budgetary constraints, and project timelines.

The important thing is to choose a reliable steel pipe supplier, you can trust China Carbon Steel Pipe manufacturers—UNIASEN. We ensure the selection of the type of steel pipe that best suits your project, thereby contributing to its success and sustainability.