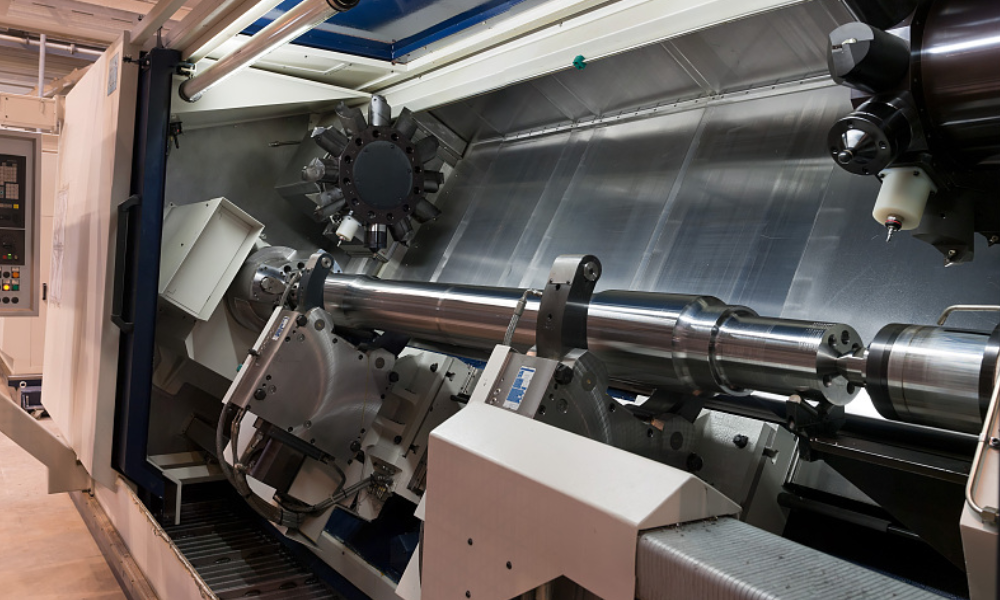

carbon steel ERW pipe Factory

ERW Steel Pipe(Electric Resistance Welded Pipe), Carbon Steel ERW Pipe

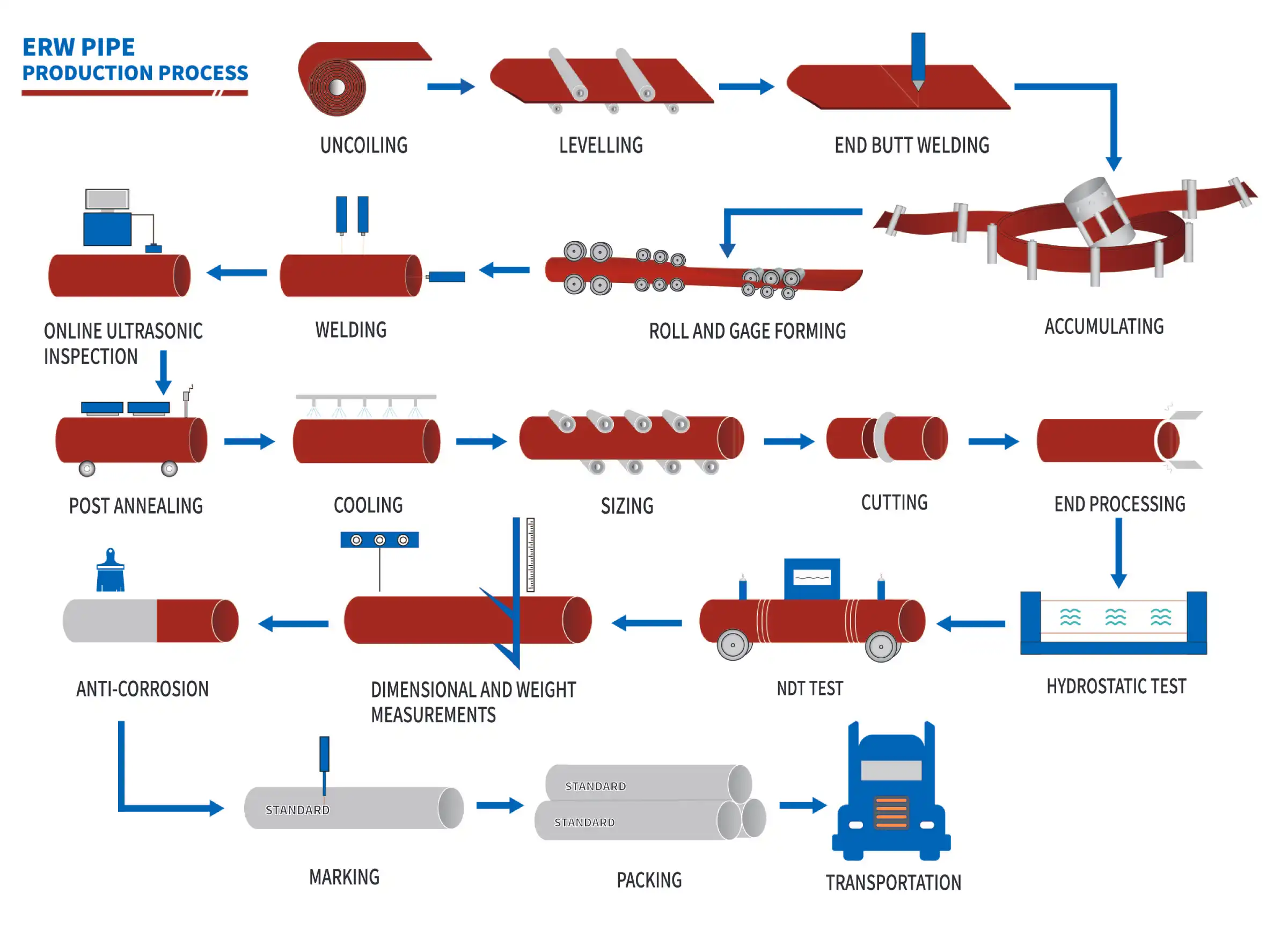

Electric Resistance Welded (ERW) pipe is made from high-quality carbon steel coils, cold-formed into a cylindrical shape with a longitudinal weld parallel to the pipe.

Uniasen is a trusted wholesale ERW pipe supplier in China. Our ERW pipes are manufactured using advanced automated welding lines and are available in diameters up to 24 inches (610 mm) to meet different industry needs. The coil width matches the circumference of the pipe, ensuring performance for the transportation of oil, gas, and various liquids or steam.

Our pipes range in size from 1/2 inch to 24 inches, suitable for welding, threading, grooved, and bending, providing versatility for projects around the world