china carbon steel erw pipe Factory and Exporter

ERW Steel Pipe(Electric Resistance Welded Pipe), Carbon Steel ERW Pipe

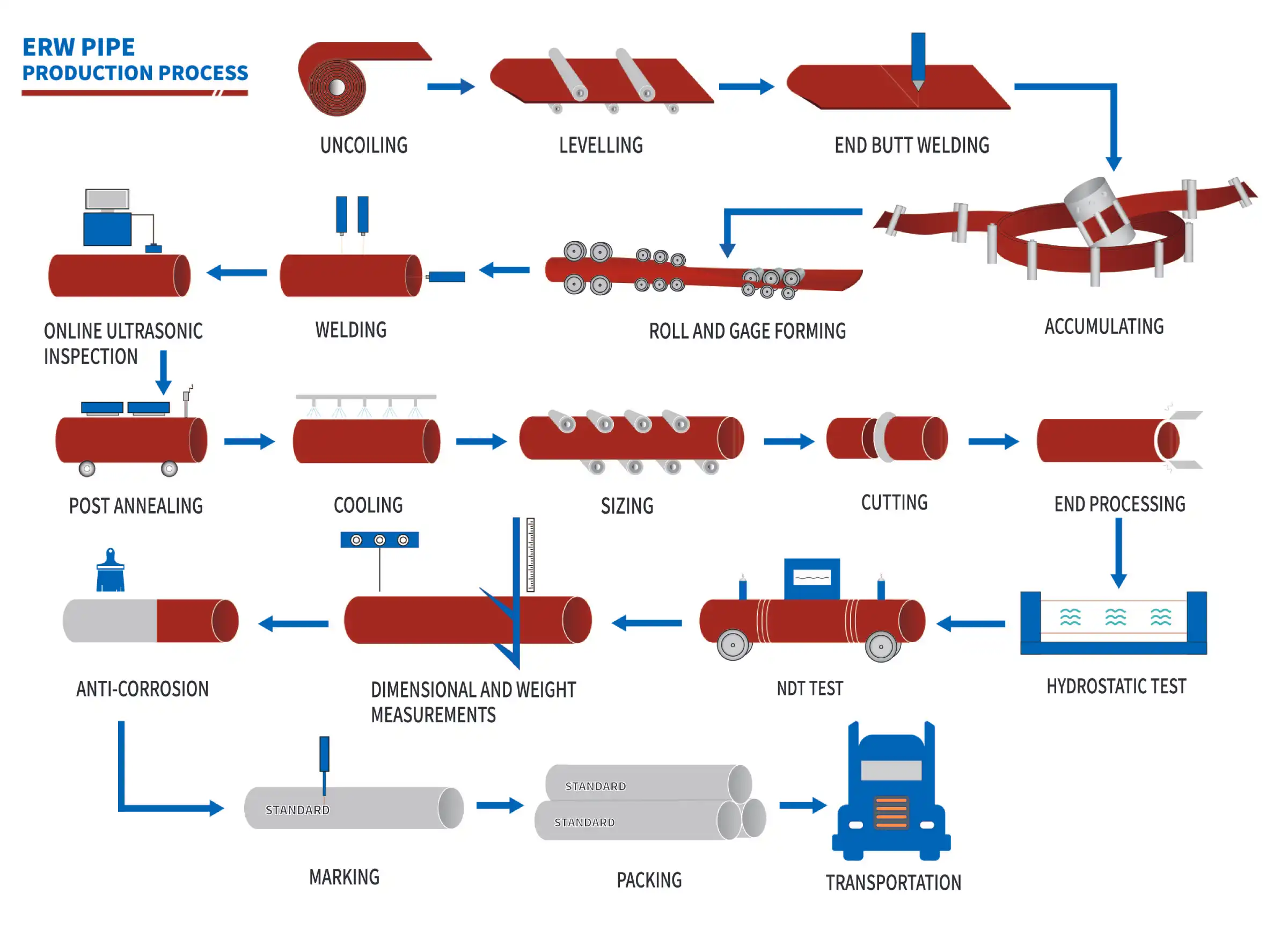

ERW (Electric Resistance Welded) pipes are produced through the cold forming of a steel coil, shaping it into a cylindrical form.

These pipes are created by forming the steel coil, and the resulting weld seam aligns parallel to the pipe.

Due to the coil’s width being equivalent to the pipe’s circurtation of oil, natural gas, and various vapor-liquid substances, catering to diverse high and low-pressure specifications.

Request ERW Welded Steel Pipe Quote