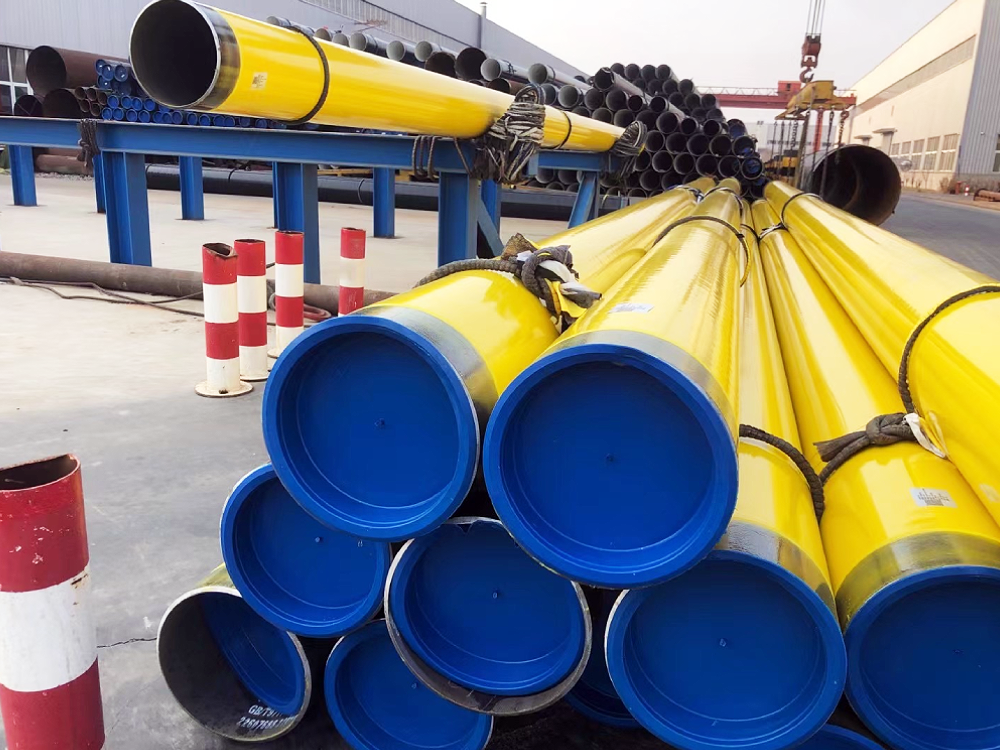

API 5CT Casing and Tubing

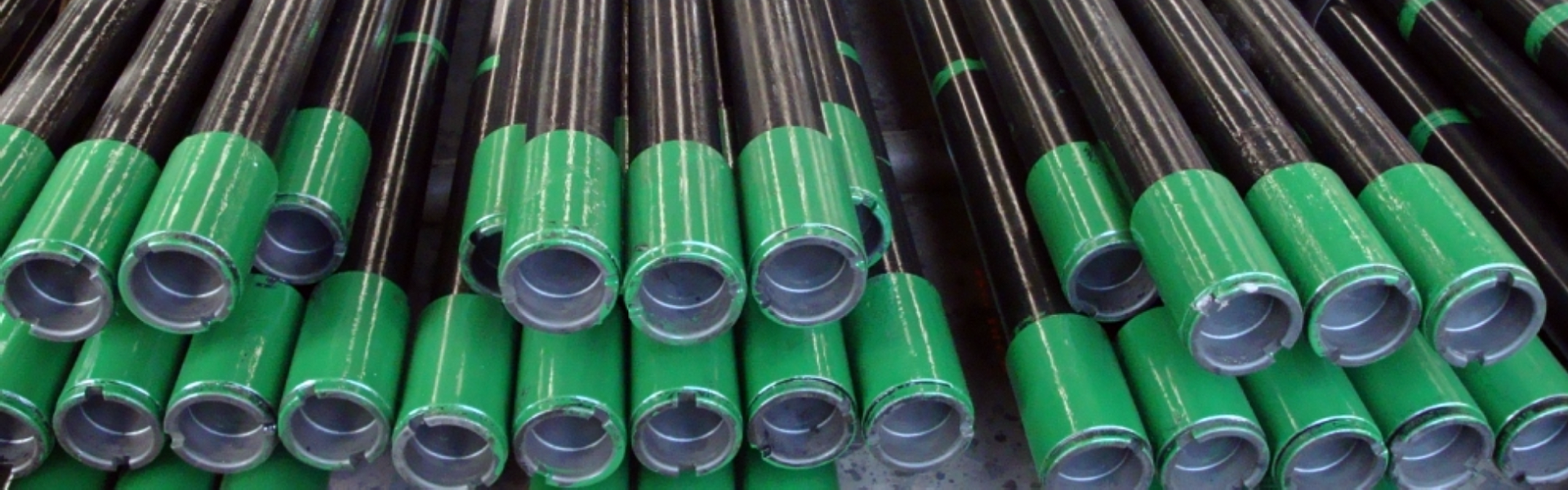

The API 5CT standard’s main purpose is to ensure the quality and reliability of oil pipelines, wellheads, and oilfield equipment.

In addition to casing and tubing, it also includes pup joints, coupling blanks, coupling materials and accessory materials. We offer a range of options to suit your specific needs across three product specification levels (PSL-1, PSL-2 and PSL-3).

PSL-1 is the basis of this standard and PSL-3 is robust.

At UNIASEN, we offer premium quality API 5CT casing and tubing designed to meet the stringent requirements of the oil and gas industry.

Get An Instant Quote