UL Listed Fire Pipe

UL certified fire protection pipes refer to products that have passed rigorous testing by the UL safety laboratory in the United States. Such pipes can stably transport water or fire extinguishing media in fires.

UL certification is a globally recognized safety standard, especially in North America, the Middle East, Southeast Asia, and other places. Such pipes have material strength, corrosion resistance, high pressure resistance, and other properties. Large-scale projects require the use of UL certified fire protection products.

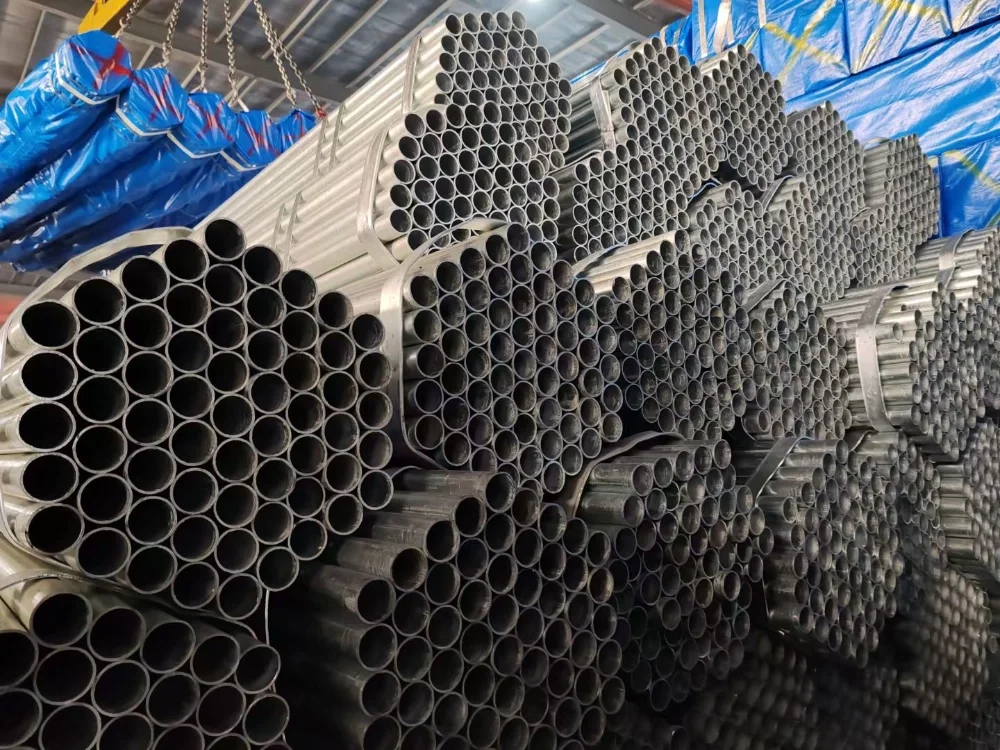

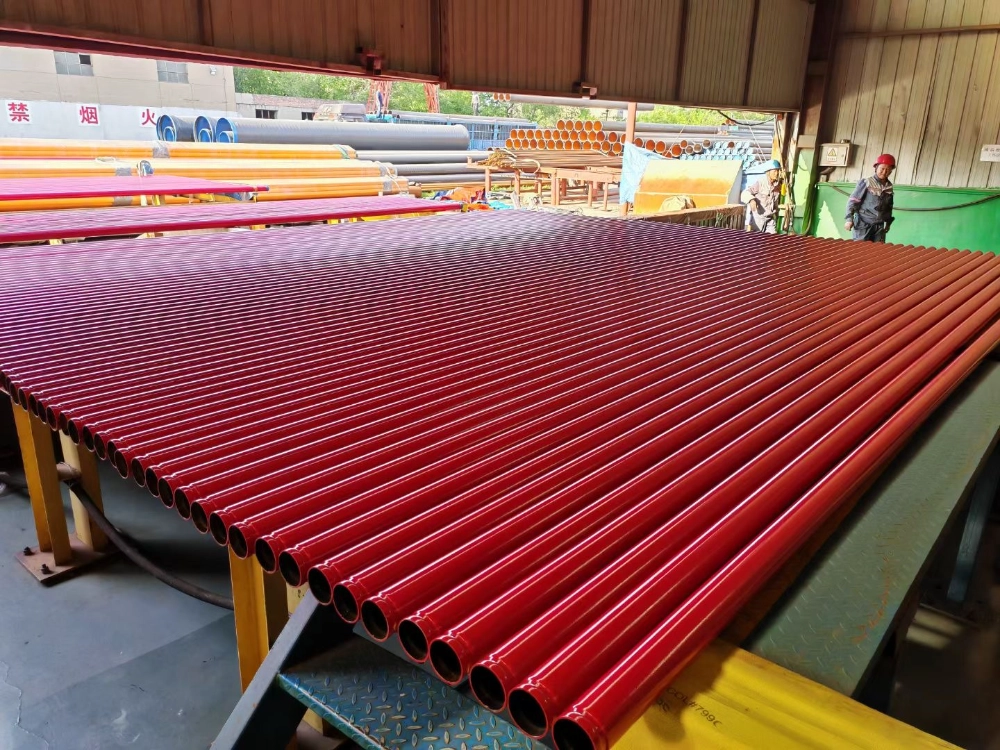

UNIASEN’s UL certified fire protection pipes come in several types: galvanized, black steel, and painted. They meet UL 852 standards and are ideal for commercial buildings, factories, and warehouses.