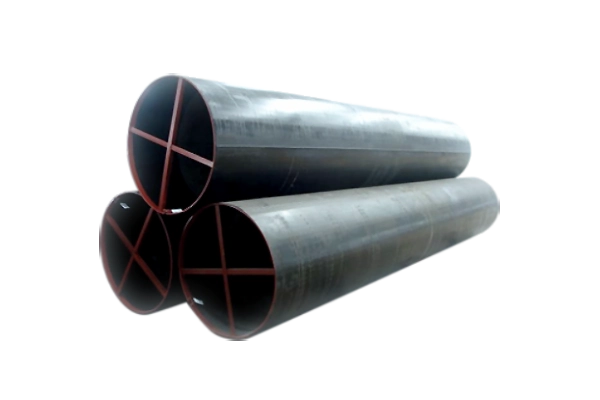

DIN 1626 Pipes Supplier in China

Standard Overview:

DIN 1626 specifies the technical requirements for welded steel pipes for pressure applications.

Main materials:

Non-alloy and low-alloy steels, with St 37.0 and St 44.0 being the most common steel grades.

Applications:

Welded steel pipes to DIN 1626 are widely used in industries that need stable pressure control. These include supply chains, processing plants, and storage tanks. They work best in low to medium temperature and pressure.

UNIASEN’s welded steel pipes strictly follow DIN 1626. This ensures high reliability and durability for various industrial uses.

Get A Free Quote