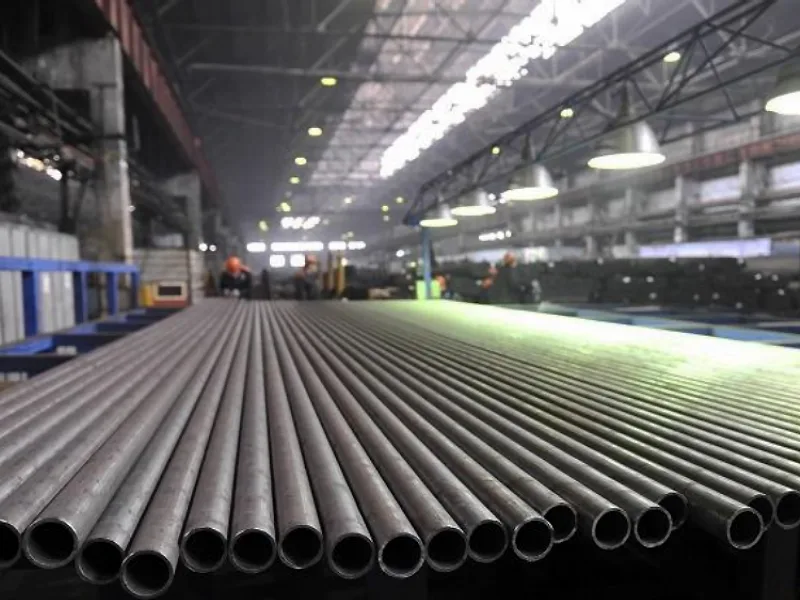

AS1163 Cold-Formed Structural Steel Hollow Sections

AS1163 is the standard for cold-formed structural steel hollow sections in Australia and New Zealand. It specifies the requirements for the production and supply of electric resistance welded (ERW) sections used in structures. These high-quality hollow sections are manufactured by cold forming and do not require heat treatment. You can choose from three strength grades: C250, C350 and C450. These grades are available with or without impact properties and are ideal for welding and a variety of structural uses.

The AS 1163 standard is designed to provide manufacturers and suppliers with a consistent specification for determining the production requirements for cold-formed electric resistance welded steel hollow sections. The dimensions, tolerances and other relevant properties listed in the standard are compatible with current manufacturing technology and practice.

Get A Quote