Introduction

Corroded metal or carbon steel pipes are restored through processes known as pipe lining and pipe coating. The plumbing, water supply, gas supply and industrial processes are based on pipes. Pipes are also necessary for domestic use. Due to environmental changes, these pipes deteriorate through corrosion, abrasion, or exposure to chemicals. Although both techniques aim to achieve the same objective, they employ different procedures and applications.

In this article, you will get to know about each strategy and its pros and cons, as well as how to decide which strategy to adopt when doing your project.

What is Pipe Lining?

Definition

Another name for pipe lining is Cured-in-Place Pipe (CIPP) lining, which involves fixing the existing pipe. It is a time-consuming process and requires investment to repair damage. The formation of a new pipeline within an existing damaged one is the key concept of the process. The process of how the pipe lining works is as follows:

- In the initial step, a camera is used to identify the damaged area. Once it is identified, the area is cleaned of any grease or debris to avoid hindrance in the restoration process.

- A resin or epoxy-coated liner is inserted inside the pipe, near the damaged area. The liner is inflated, filling the gap, and a new pipe is created within.

- The application of heat or UV rays causes the resin to adhere to the surface very firmly.

- Finally, the damaged area is inspected with a camera to review whether the gap inside the pipe has been properly filled or not.

Advantages

The primary use of pipe lining is to repair damaged areas of the pipe. This process has many advantages, such as:

· Non-invasive installation

Pipe lining is unlike full pipe replacement. It does not require a big excavation, which leaves property owners with the expensive task of restoring the landscape or the floor.

· Long life

A lined pipe, properly applied, will last 40-50 years, which is a significantly longer lifespan than a traditional pipe.

· Corrosion resistance

Epoxy lining prevents internal corrosion and is resistant to chemical attack, making it suitable for use in various environments.

· Less downtime

Reduced downtime means that many projects can be completed in 24-48 hours, causing less disruption to businesses and homeowners.

· Flexibility

It fits within pipes with curves, joints, and irregular forms, making it flexible in complicated systems.

Disadvantages

· Greater initial expenses

Pipe lining is more costly than pipe coating due to the use of resin or epoxy materials and the associated curing technology.

· Poor access

Pipes with extreme collapse or blockages may not be able to be lined without partial replacement. The pipes that are extremely damaged cannot be cured by this process.

· Reduction of the diameter

As the liner provides thickness to the inside of the pipe, it decreases the inside diameter of the pipe by a slight margin. In small pipes, this may affect the capacity to flow.

What is Pipe Coating?

Pipe coating refers to the process of applying a protective layer to the inside or outside of a pipe, typically using epoxy, polyurethane, or polyethylene. The coating does not form a new pipe, but rather forms a shield against corrosion, abrasion, and erosion.

Two major methods are used:

- External Coating: The pipe is stripped, re-coated on the outside, and then reinstalled.

- Internal Coating: The liquid coating is applied by sprinkling or spraying it into pipes, where it dries into a thin, protective coating.

The process is similar to the pipe lining, which means that:

- The initial step involves inserting a camera to inspect the pipe and removing dirt, grease, or debris.

- In the next step, the coating is sprayed inside the pipe, which is then dried, and serves as a protective layer inside the steel pipes.

- The layer provides extra protection from corrosion and chemical damage, making the pipe more durable.

- Finally, the pipe is inspected with the aid of a camera to identify any areas of the pipe that are not coated properly.

Pipe coating is used in other industries, such as oil, gas, and water treatment, where a longer lifespan of structurally sound pipes is needed.

Advantages

· Economical

Pipe coating is comparatively cheaper than lining, and installation is typically 20 to 30 percent cheaper.

· Corrosion protection

It prevents rust and chemical corrosion (particularly in metal pipes that are exposed to water or gas).

· Enhances flow efficiency

A smooth internal coating will create low friction, enhancing fluid velocity and lessening pumping expenses.

· Broad applicability range

It can be applied to either new or existing pipes, irrespective of their diameter or material.

· Quicker installation

It is easy to install, and less preparation is required as compared to lining.

Disadvantages

· Restrict Repair

This process is used to make the pipes more durable; it cannot be used to repair damaged parts.

· Systemic Problems May Not Be Addressed

Underlying issues, such as mineral accumulation or poor water pressure, cannot be fixed by coatings.

· Application Determines Longevity:

The original pipe’s state and the Caliber of the coating’s application determine how long the coating lasts and can eventually affect its effectiveness.

· Breakdown of Elements:

Extreme weather conditions such as wind, rain, and sunlight can degrade coatings and reduce their protective capacity.

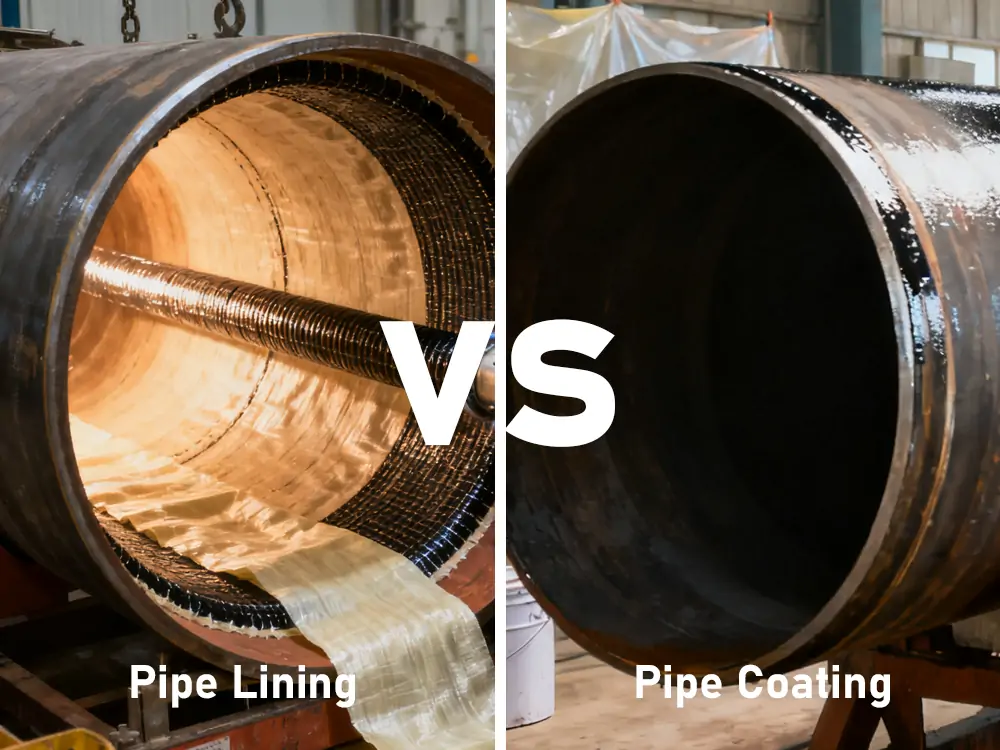

Pipe Lining vs. Pipe Coating

Both process pipe lining and pipe coating are used to increase the lifespan and enhance the protection of carbon steel pipes. Here is the summary of the differences between the two processes:

| Features | Pipe lining | Pipe coating |

| Function | In this process, a new pipe is built inside the old one. | Application of the protective layer inside and outside of the pipe. |

| Cost | Higher initial investment | Lower cost |

| Life span | 40-50 years | 15-20 years |

| Efficiency | Reduce the diameter to reduce the material flow. | Smooth coating increases the fluid flow. |

| Usage | For repairing the damaged pipes. | For improving the lifespan of the pipes. |

UNIASEN—Quality Coated Pipe Manufacturer

In projects where pipe coating is considered necessary, the relationship with a reputable manufacturer becomes of great importance. UNIASEN is a leading supplier of coated pipes, meeting the diverse needs of various industries. The company is using hot-dip galvanizing, polyethylene, PP and Epoxy coating. Different FBE-coated pipes are coated in the industry, like dual-layer FBE, 2LPP, 3PE, and 3PP coated pipes. They provide the pipes with external and internal coating that protects the pipes from corrosion and abrasion.

- Coated pipes with us have proven great resistance against corrosion, chemicals, and abrasion.

- Every product is put through rigorous quality control procedures and is guaranteed a long lifespan even under extreme conditions.

- Coated and lined pipes of various diameters and materials are supplied for the oil and gas, water treatment, and construction industries.

- Coated pipes are guaranteed to have an amazing ROI as the maintenance and repair costs are lowered, in addition to the lifespan of the pipes being enhanced. The company places a great emphasis on compliance and avoids penalties.

- The insulation by the coating and lining provides temperature resistance and insulation to the steel pipes.

Conclusion

All in all, piping lining and coating techniques offer distinct advantages in pipeline rehabilitation.

- Lining provides structural support and extends the life of a severely deteriorated pipe by up to 50 years.

- Cost-effective coated pipes protect structurally sound pipes and also improve flow efficiency, lasting 15–20 years.

Your pipes’ condition, budget, and long-term targets will shape the final choice. Evaluating all options and collaborating with reputable suppliers, such as UNIASEN, will ensure optimal functionality, reduced downtime, and extended lifetime performance of your piping systems.