Pipe beveling is not only a preparatory step, but an important factor in the longevity and quality of your piping system. Whether threading or welding, beveling ensures successful pipe assembly and efficient operation.

Carbon steel pipes are essential components in numerous industries, known for their strength and versatility. Commonly used in construction and for transporting liquids like water and oil, these pipes are manufactured from steel ingots or solid round steel. The production process involves perforating the steel to create capillary tubes, followed by methods such as hot-rolling or cold-rolling. With carbon as the primary alloying element, carbon steel pipes offer durability and reliability, making them a preferred choice for various structural and fluid transmission applications.

The seamless steel pipe manufacturing process involves heating high-quality steel billets to around 2,370°F (1,300°C) and piercing them with a mandrel to form a hollow tube. Two main methods are used: the Mannesmann cross-rolling technique and extrusion. These processes produce durable, seam-free pipes, widely used in industries requiring high strength and reliability.

Both black and galvanized steel pipes are standard in our daily routine. From oil transportation piping to home water pipelines, they ensure our sustainability. However, as both are made of steel, people consider them the same. This is wrong because there are many differences between Black and Galvanized Steel Pipe. Are you one of…

Black steel pipes offer notable advantages due to their exceptional strength and durability, allowing them to withstand higher pressures compared to other materials. However, their heavier weight can make installation more challenging and time-consuming. Despite these drawbacks, with appropriate maintenance, they provide a long service life, reducing the frequency of replacements.

Pipe coatings play a crucial role in protecting pipelines from corrosion and environmental damage. This blog delves into the different types of pipe coatings available, such as fusion-bonded epoxy (FBE), polyethylene, and coal tar enamel. Each coating type offers unique benefits suited to various applications, including wastewater systems, petroleum pipelines, and industrial environments. By understanding these coatings’ properties and uses, industries can make informed decisions to ensure the longevity and efficiency of their pipeline systems.

ASTM International, formerly the American Society for Testing and Materials, is a leading organization that develops and publishes voluntary consensus standards used globally. These standards span across diverse industries, including metals, textiles, and construction, to ensure quality, safety, and performance. With over 12,000 standards in its portfolio, ASTM plays a vital role in fostering innovation, consistency, and reliability in materials and processes worldwide.

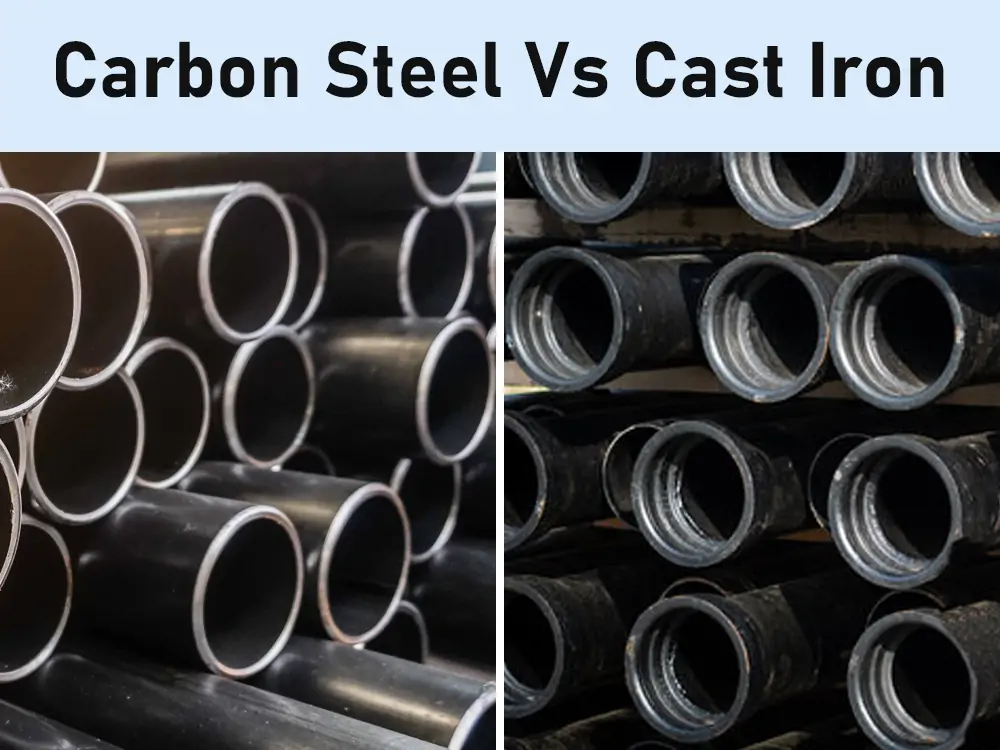

Cast iron pipes and carbon steel pipes have distinct differences in their applications, characteristics, and classifications. High carbon steel is known for its high strength and hardness, but it has low ductility, toughness, and poor weldability. Steel pipes are far more durable, stronger, and lighter compared to cast iron pipes, making them easier to transport and install.

Pipeline transportation is a highly efficient method for transporting liquids and gases, offering continuous flow, reduced traffic congestion, and lower accident rates. However, it involves high initial construction costs and poses environmental risks, such as leaks and spills, which can cause significant ecological damage.

ERW (Electric Resistance Welded) pipes are steel pipes manufactured using a resistance welding process, which can employ either low-frequency or high-frequency resistance to join the edges of steel strips into a tubular shape. This method is known for its high production efficiency, cost-effectiveness, and material-saving benefits, making ERW pipes widely used in various industries.

Understanding the difference between black iron pipe and black steel pipe is essential to choosing the right pipe material. This article provides an in-depth comparison of the differences between black iron pipe and black steel pipe in terms of composition, application, durability, cost and maintenance to help you make an informed decision. Whether you are engaged in construction, plumbing or home improvement, this article will provide you with valuable reference information.

A seamless pipe is manufactured without any welds or seams, using a process that extrudes metal into its desired shape. This production method results in a pipe that offers enhanced strength and pressure resistance, making it ideal for high-pressure applications, oil and gas transmission, and structural components. Seamless pipes are known for their smooth internal and external surfaces and are available in various sizes and materials.

SCH 40 and SCH 40S are pipe schedules that specify wall thickness for steel pipes. SCH 40 is widely used in various industries for its standard thickness, while SCH 40S has slight differences tailored for specific applications. This article clarifies their definitions, key distinctions, and appropriate uses, aiding in making informed choices for industrial and construction projects.

Galvanized pipes, although durable for up to 60-70 years, eventually corrode, leading to rust buildup and potential lead contamination in your water supply. This deterioration can cause noticeable rust stains, leaks, and even complete pipe failure. Replacing galvanized pipes with modern materials is crucial for maintaining a safe and efficient plumbing system, ensuring all rust and lead are removed, and preventing future plumbing issues.

ASTM A53 steel pipe is mainly used for conveying fluids and gases, while ASTM A500 steel pipe is mainly used for structural applications. Due to different manufacturing and design standards, A500 steel pipes generally have a higher strength-to-weight ratio.

When it comes to piping systems, pipe sleeves are a common but important component. Pipe sleeves are small sections prefabricated from various original pipes and pipe accessories, including flanges and fittings. They are manufactured off-site to reduce assembly time and are pre-cut to exact sizes, including various accessories such as flanges, elbows and tees.

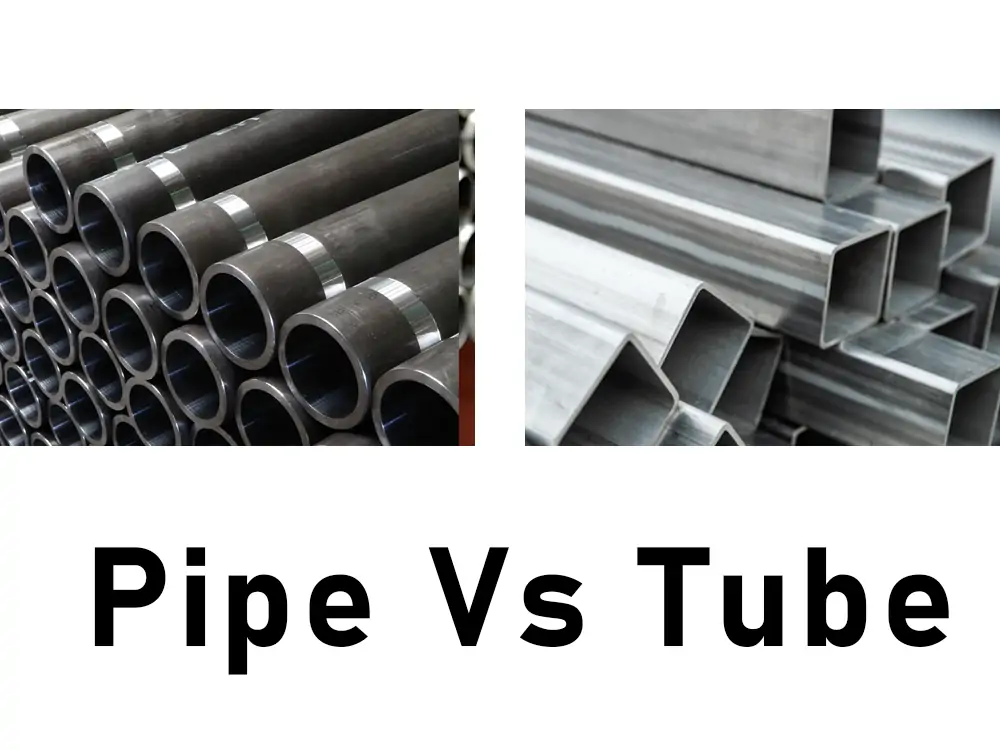

Steel pipes and steel tubes, while often used interchangeably, have distinct differences. Steel tubes are generally stronger and used in structural applications like building frames, furniture, and automotive components, while steel pipes are commonly used for transporting fluids and gases.

Seamless steel pipe is a steel pipe without welds, which is processed from a solid cylindrical blank through multiple perforations. It has the advantages of high-quality materials, high precision, excellent mechanical properties, and no welds. This article introduces the top ten outstanding seamless steel pipe manufacturers in the world in 2024. These companies have an important position and influence in the seamless steel pipe industry.

This article takes an in-depth look at two piping options commonly used in construction and engineering projects: Schedule 20 and Schedule 40. Their respective wall thickness differences, pressure-bearing capabilities and applicability were compared and analyzed.

In different industries, people use metals for various applications. Two of these metals are aluminum and steel. Metals can be divided into two groups. These are ferrous and non-ferrous metal groups. Aluminum and steel are two metals that we can use for many different things. In manufacturing industries, aluminum and steel play a crucial role….