There are a lot of products and fittings available in the market. The choice of a specific fitting for the steel pipes is a very time-consuming task. Users conclude that the carbon steel fittings are reliable, offering a wide range of options that can resist high temperatures and pressures. In this article, you can learn…

Introduction Schedule 20 pipes are thin-walled, low-pressure-rated pipes. “Schedule” is a standardized term indicating a pipe’s wall thickness. It aligns naturally, therefore, that Schedule 20 pipes have less wall thickness than Schedule 40 and Schedule 80 pipes. Commonly made from carbon or galvanized steel, Schedule 20 pipes are easy to slice, form, and fit. Schedule…

Introduction The selection of the type of pipes is essential when constructing any system that uses pipes. Two standard options are Schedule 10 (Sch 10) and Schedule 40 (Sch 40). These pipes have numerous applications in plumbing, building, and construction, as well as in chemical plants and various industries. These two types may seem similar…

Steel and carbon are combined to create seamless carbon steel pipes. They’re not welded. These pipes are helpful in a variety of industries, including power, oil & gas, infrastructure, and construction. As the demand increases, the supply of Carbon steel pipes has gained more usage over time. The mix of carbon and steel makes it more…

You might be familiar with carbon steel pipes. They are strong and versatile, with numerous applications in various industries. Several key considerations are critical before a manufacturer chooses a carbon steel pipe. One such consideration is the pipe schedule. Schedule is a standardized method of describing the wall thickness of pipes. Commonly seen schedules are…

There are few pipe materials as versatile as carbon steel. Some of it stems from the simplicity of this pipe, made up of just carbon and steel. The amount of carbon, however, can make an enormous difference to the pipe’s properties. In general, carbon steel pipes contain between 0.03% to 2% carbon. The majority of…

Overview of ASTM A500 ASTM prescribes the A500 standard for structural carbon steel tubing. A500 pipes come in three different forms: square, circular, and rectangular. This class of structural tubing is characterized by its cold-formed production process. The manufacturing process determines another critical attribute: welding. ASTM A500 pipes may be seamless or welded by nature….

Hollow Structural Section (HSS) steel pipes are construction steel pipes with high tensile strength and load-bearing applications. There are three broad types of HSS steel pipes: circular, rectangular, and square. HSS steel pipes are critical in structural applications due to their high strength-to-weight ratio. They see widespread use in infrastructural projects, industrial settings, and…

Steel pipes used in industrial operations fall into two categories: seamless and seamed. Understanding their differences is essential to evaluating which is best for you. Overview of Seamless Steel Pipes Seamless pipes are considered stronger and more reliable than welded pipes due to their uniform structure and absence of welds or joints. As you might have guessed by the name,…

ASTM A500 Technical Specifications The American Society for Testing and Materials prescribes the A500 standard for carbon steel pipes and tubing. It consists of exhaustive material, physical, and metrological requirements. Steel tubes that meet these specifications are approved as A500 standard pipes. A500 pipes are characteristically cold-formed and seamlessly welded. They are manufactured in a…

One of the most widely seen pipes in the industry is the straight-seam welded pipe. Various manufacturing processes are used to fabricate these steel pipes. Due to these, they have different properties, dimensions, and applications. Today, we will discuss two crucial techniques of steel pipe fabrication in depth. We are talking about high-frequency resistance welding,…

Today, we will analyze two fundamental types of pipes used in industrial applications. Carbon steel pipes are robust, long-lasting, and offer high tensile strength. Black steel pipes are rigid, general-purpose steel pipes used in many scenarios. Both pipes have distinct advantages and perform optimally in specific use cases. They are used in several industries, such…

Mild steel pipes, known for their low carbon content (under 0.25%), offer a unique combination of softness, flexibility, and moderate strength. These pipes exhibit good ductility, weldability, and corrosion resistance, making them cost-effective and easy to fabricate.

OD, ID and nominal pipe size are key parameters in pipe selection. This article will explain the differences between the three in detail to help you understand how to choose the right pipe size based on project needs to ensure the best results for pipe installation and system operation.

Epoxy pipe coatings are a durable and cost-effective solution for extending the life of pipes, with some lasting up to 100 years. They offer quick application, reducing downtime compared to traditional repiping methods, and can save up to 50% in costs.

The top 15 carbon steel pipe manufacturers in 2025 demonstrate their innovation, quality standards, and market influence. These companies are located in different regions and have been selected for their outstanding contributions to the construction, oil and gas, and industrial sectors.

Fire sprinkler systems typically use three types of pipes: steel pipes (black and galvanized), copper pipes, and CPVC (chlorinated polyvinyl chloride) pipes. The choice of pipe depends on factors like system size, location, cost, and environmental conditions. Each pipe material has its own set of advantages, ensuring optimal performance and safety in fire suppression systems.

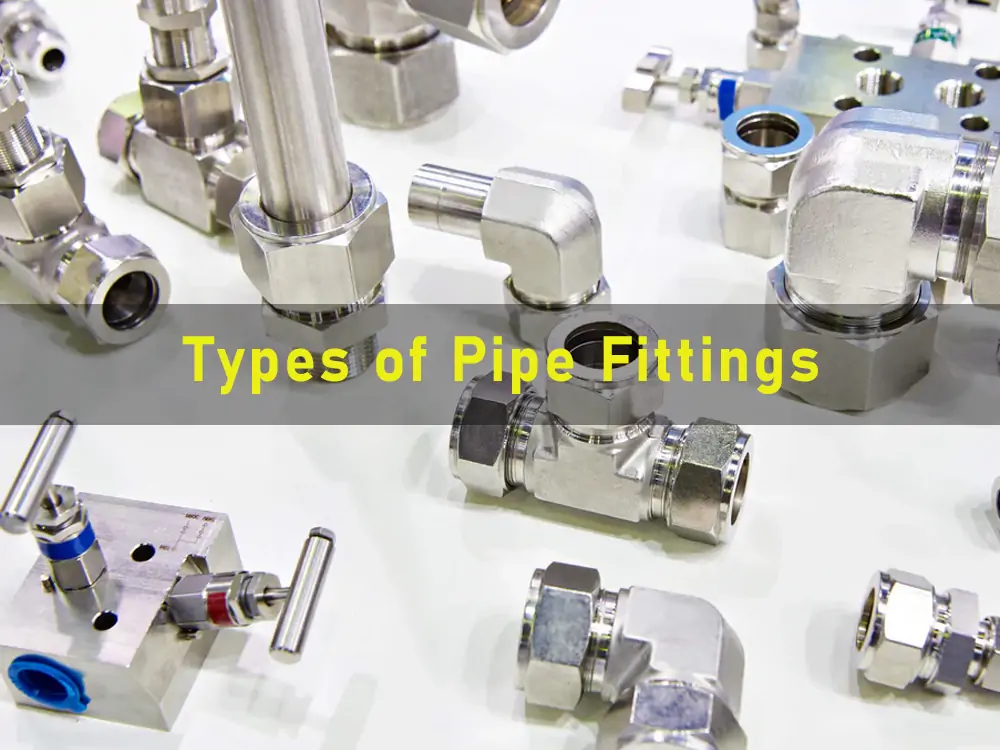

This article explores the various pipe fittings and their uses, covering common fittings such as elbows, fittings, unions, adapters, couplings, reducers, tees, and crosses. These pipe fittings play important roles in pipe systems, such as connecting pipes, changing flow direction, or adjusting pipe size.

When comparing carbon steel pipes and galvanized steel pipes, the main considerations are their strength, corrosion resistance, and applicable scenarios. There are significant differences in material composition, surface treatment, and performance characteristics, giving them advantages in different applications.

Introduction ASTM A53 is a steel pipe specification developed by the American Society for Testing and Materials (ASTM). This standard defines the material characteristics of pipes used in plumbing, heating, gas, and other critical applications. Due to their versatility and strength, ASTM A53 pipes are widely used in construction, manufacturing, and industrial projects. The standard includes different…