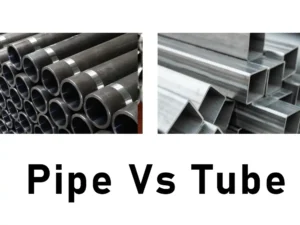

Although steel tubes and pipes may sound similar, they are not!

Their characteristics and usage are different. Every newcomer misunderstands them due to their similar shape and material.

So, what are the differences between a steel pipe and a steel tube?

Steel pipe is rigid and circular and is used to transfer liquids and gases.

However, steel tubes are flexible and can have different shapes. These include round, rectangular, square, oval, or straight. Tubes are usually used in the medical industry.

Many other contrasts make both of these bulls apart. This guide will highlight the disparities between steel tubes and pipes and help you better understand them. So, let’s jump into it!

Differences Between Steel Pipe and Steel Tube

Steel pipes and tubes are actively used around us.

However, they are usually miscomprehended as one. Although both consist of steel, they do not serve the same purpose.

According to their properties, both have different uses.

Steel pipes are primarily used for transferring liquid and gasses from one location to another.

What makes steel pipes in demand is their flexibility. They can be changed into any shape with ease.

In the section below, I will explain their fundamental differences to ensure you don’t confuse them together.

1. Classification/Measurement

Steel pipes and tubes are classified based on how their size is specified.

Pipes are measured in terms of inside diameter (ID) and schedule number (thickness).

On the other hand, the tubes are selected based on the outside diameter (OD) and wall thickness.

NPS is a standardized way of mentioning any size of pipe.

For example, for a pipe that is 6 inches in length, NPS 6 is typically used. It indicates that the pipe has an inside diameter of 6 inches.

For measurement of the thickness of the pipe, Schedule No. Is used.

Notably, NPS (Nominal Pipe Size) reading is never 100% accurate.

Usually, the manufacturer puts a label on the pipe with a reading written in NPS. The actual measurement of the pipe is slightly different (neglectable).

The manufacturers and engineers ignore such minor differences. So, they consider NPS as standard.

2. Shapes

Both of these two types differ in terms of their shapes.

Steel pipes are usually circular, carrying fluids, gases, and other things. These fluids and gases put pressure on the pipe during flow, so the circular shape allows pipes to bear the pressure.

The steel tubes are more flexible when it comes to the shape.

They can be circular, rectangular, oval, or in any shape. The reason is that they are not rigid and can be drawn into any shape.

So, the manufacturer takes advantage of this and changes it to any shape they need.

However, both are tubes, and pipes are hollow structures.

3. Tolerance

Tolerance is one of the most critical factors regarding steel tube vs. pipe.

It is defined as the size change a product can have without changing its function or performance.

Simply put, tolerance is the acceptable range within which the dimension of a steel product can change.

Steel pipes come with high tolerance. This means that pipes do not change their performance, even if they change their size or dimension.

Steel tubes, on the other hand, come with stringent tolerance. Small changes in their properties will alter their performance.

4. Manufacturing Processes

Steel pipes are usually produced using a hot-rolled process.

In this method, the steel billet is heated to 926°C. It is less expensive but does not offer smooth finishing.

Steel tubes are cold and hot rolled depending on the needs of manufacturers.

However, they are usually made by cold rolling. This is because it offers excellent finishing and smoothness to the surface.

Remember that cold rolling ideally provides strict tolerances to the tubes.

5. Telescoping Abilities

Telescoping is an essential factor to consider in construction work.

A tube can slide or fit inside one another. It helps make joints and adjust the configuration of tubes.

The steel pipes do not support telescoping efficiently.

On the other hand, the steel tube is an excellent option for telescoping. The reason is that the tubes have smooth interiors and superb finishing.

It allows two tubes to fit each other from the inside easily. For telescoping, DOM tubing is the best choice.

6. Strength

Both steel pipes and tubes offer decent durability.

However, tubes are more robust and perform better in the long term. Their durability and withstanding in harsh conditions are also top-notch.

There are multiple reasons for the greater strength of tubes.

First, a steel tube’s structure is more uniform than that of a steel pipe. It is produced through multiple complex steps, including cold and hot-rolled processes.

Above all, it is thicker than the pipes, so the tubes perform better and offer excellent durability.

7. Rust & Corrosion

Both steel pipes and tubes are prone to rust. Once you use them, they will start showing signs of rust. Rust is more problematic in steel pipes. Pipes carry fluid, and rust mixes with fluid, contaminating it.

However, the manufacturer applies a zinc coating to the interior of both pipes and tubes. This coating protects them from rust and increases their longevity. Keep in mind that it is not a perfect solution. For an ideal solution, you should use stainless steel pipes, as they don’t get rusty.

These stainless steel pipes and tubes are more expensive—ten times more. However, if rust protection is mandatory in your project, you should go with stainless pipes. In the long run, these pipes prove to be cost-effective.

8. Applications

Both pipes and tubes are extensively used in different industries. Their usage mainly depends on the requirements of the manufacturers. Steel pipes are used to transport liquid and gasses. They are the perfect solution for underground water transportation in the cities.

The steel tubes are flexible and can be changed into any shape. This is why they are usually used in the medical industry. Moreover, their usage is common in making trailer frames, furniture, etc. Here is a table showing their applications:

| Applications of Steel Pipes | Applications of Steel Tubes |

| Transportation of oil, gasses, chemicals, and use in water supplies | Used in bridges and towers due to the excellent flexibility of steel tubes |

| Used in construction, for example, piling for foundations, columns, beams, etc | Used to manufacture trailer frames and furniture |

| Used in plumbing work in houses and offices for water distribution | Used in vehicle chassis, roll cages, exhaust system, suspension, etc |

| Used for ductwork and conveying hot or cool air throughout buildings | Used to manufacture racks such as refrigerator racks and oven racks |

| Helpful in manufacturing fences and handrails for safety purposes | Steel tube is suitable for agricultural equipment such as tractors, plows, etc |

How to Order Steel Pipe and Tube?

Ordering steel pipe and tube can be a bit tricky. However, knowing the specifications and requirements of your required steel type makes it a lot easier. Keep in mind that the steel pipe and tubes are specified differently.

You must mention the inner diameter or NPS (nominal pipe size) and the schedule Number for steel pipes. For ordering steel tubes, mention the outer diameter you need and the wall thickness of the tube. The most crucial step is to find a reliable supplier.

Steel pipes and tubes are expensive. Choosing an inefficient and unreliable supplier can result in mishaps that you would like to prevent. Therefore, search for online steel pipe and tube suppliers with a previous track record and good reputation. UNIASEN has more than 20 years of experience in steel pipe manufacturing and exporting. Contact our steel pipe professionals to get free quotes.

Is Steel Pipe Efficient & Cost-effective?

Yes, steel pipes are less expensive than steel tubes.

This is due to the simple manufacturing process of steel pipes.

Unlike tubes, pipes are less complicated as well.

However, the efficiency of steel pipes depends on the needs and preferences of the buyer.

If rust protection is your priority, steel pipe won’t be ideal. You’ll have to get a galvanized steel pipe to ensure that corrosion does not affect the pipe’s longevity.

Pipes usually carry liquid, so rustproofing is vital.

If you need flexibility, a steel tube would be a better option. Although it is more expensive, it will serve your purpose well.

Steel pipes are rigid. Their effectiveness and efficiency depend on their usage.

Interesting Note: The manufacturing of steel tubes is too costly. It requires expert labor, energy, and raw materials. Multiple complex steps are involved in its production. So, it is not for those who have a tight budget.

Conclusion

Steel pipe vs. tube is least understood. Everyone comprehends both of these as one material. You need to update your knowledge base if you are one of them. And this guide is going to be the perfect match for you.

I’ve explained all the differences between steel pipes and tubes. After reading, you’ll learn which one is good for what. Whether you need a pipe or tube for your next project depends on your project type, goals, and preferences.