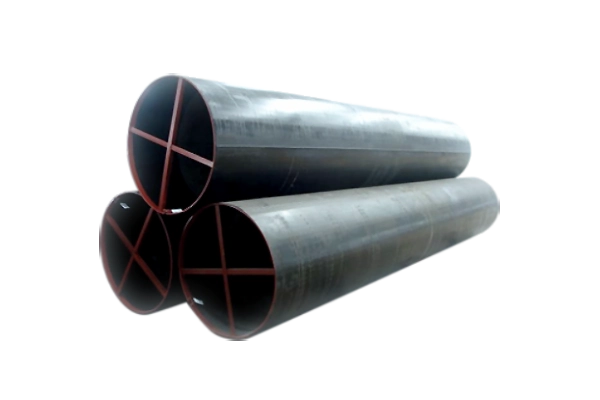

Proveedor de tubos DIN 1626 en China

Descripción general estándar:

La norma DIN 1626 especifica los requisitos técnicos de los tubos de acero soldados para aplicaciones a presión.

Materiales principales:

Aceros no aleados y de baja aleación, siendo St 37.0 y St 44.0 los grados de acero más comunes.

Aplicaciones:

Los tubos de acero soldados según DIN 1626 se utilizan ampliamente en industrias que necesitan un control estable de la presión. Entre ellas se incluyen cadenas de suministro, plantas de procesamiento y tanques de almacenamiento. Funcionan mejor a temperaturas y presiones bajas y medias.

Los tubos de acero soldados de UNIASEN siguen estrictamente la norma DIN 1626. Esto garantiza una alta fiabilidad y durabilidad para diversos usos industriales.

Obtenga una cuota gratis