Introduzione

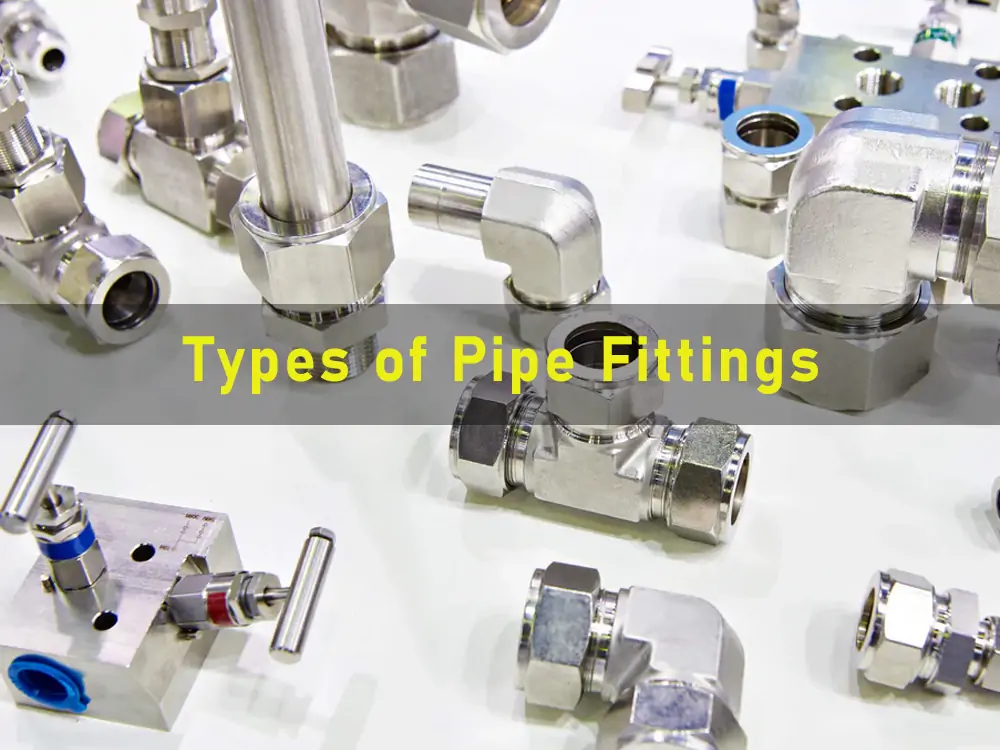

Vi siete mai chiesti come funziona il drenaggio o il trasporto dei fluidi? Le fabbriche utilizzano reti di tubazioni per guidare i fluidi attraverso varie fasi. Sono componenti fondamentali nelle fabbriche che utilizzano energia o fluidi idraulici. I tubi sono anche la spina dorsale degli impianti idraulici e di riscaldamento domestici. Tutto ciò è reso possibile dai raccordi per tubi. Essi costituiscono le giunzioni di una rete di tubi e consentono ai fluidi di piegarsi secondo angoli specifici. Sia che si vogliano unire più tubi, piegarli ad angolo o ridurre il flusso dell'acqua, i raccordi per tubi possono aiutarvi a raggiungere questo obiettivo. Vediamo oggi di familiarizzare con il mondo dei raccordi per tubi.

Che cos'è un raccordo per tubi?

Un raccordo per tubi è un componente della tubazione che collega più tubazioni. Può regolare e modificare il percorso di un fluido in un sistema di tubazioni. Ad esempio, un raccordo può collegare un tubo spesso con un tubo stretto, riducendo il volume dell'acqua. Un altro esempio può essere quello di combinare il flusso dell'acqua di due tubi in uno solo, utilizzando un raccordo a T.

I raccordi per tubi sono molto vari. Alcuni sono semplici connettori, mentre altri modificano il volume dell'acqua. Le specifiche dei raccordi e gli standard delle tubazioni sono considerazioni importanti nella progettazione delle condotte. Collegamenti non corretti possono causare perdite o danni al sistema di tubazioni. È inoltre necessario abbinare il materiale del raccordo a quello del tubo. I componenti differiscono per qualità, dimensioni, materiali e costruzione. Nelle sezioni che seguono, esaminiamo i diversi tipi di raccordi per tubazioni.

Tipi di raccordi per tubi

I raccordi per tubi sono classificati in base alle connessioni, al materiale e all'utilizzo. Questi sono i tipi fondamentali:

Maglietta

Il raccordo a T viene utilizzato per gestire il flusso di 3 tubi diversi. Presenta tre aperture disposte a 90 gradi l'una dall'altra. Queste possono essere costituite da un'entrata e due uscite o da due entrate e un'uscita, a seconda dell'utilizzo.

I giunti a T possono anche gestire il volume dell'acqua. Un raccordo a T uguale ha lo stesso diametro di entrata e di uscita. Al contrario, un raccordo a T ridotto ha un diametro del tubo di derivazione inferiore a quello del tubo di entrata.

I giunti a T sono ampiamente utilizzati nell'industria chimica per dirigere il flusso di acqua, olio, gas o composti liquidi. La semplicità del design e l'utilità dell'applicazione ne fanno uno dei connettori per tubi più utilizzati.

Wye

I raccordi per tubi Wye sono connettori a forma di "Y". Sono simili ai raccordi a T perché hanno tre aperture. I raccordi Wye hanno due aperture con un angolo di 30 o 45 gradi, che consentono un flusso combinato regolare. Vengono utilizzati in reti complesse senza sacrificare l'efficienza del flusso.

I raccordi Wye sono utilizzati nei settori industriale e di drenaggio. Nelle reti di smaltimento delle acque reflue, sono realizzati in plastica ABS, PVC o CPVC. Per le operazioni HVAC, i materiali più comuni sono l'acciaio inossidabile, il rame o l'ottone. Quando si sceglie un raccordo wye, è importante tenere presente l'esposizione media al calore e alla pressione. Le specifiche del raccordo possono variare drasticamente tra i diversi progetti.

I settori di applicazione più comuni per i raccordi wye includono impianti idraulici, acque reflue, HVAC e tubazioni. Essi diramano il flusso del tubo ad angolo, riducendo l'attrito e la turbolenza. Per questo motivo, si tratta di un'opzione ad alte prestazioni in diversi settori.

Croce

I raccordi a croce consentono di combinare fino a quattro tubi. Contiene quattro raccordi a 90 gradi. Se avete mai camminato vicino a un campo di irrigazione e avete visto la distribuzione dell'acqua, è probabile che abbiate visto il raccordo a croce in azione.

I raccordi trasversali uguali collegano tubi della stessa dimensione. I raccordi trasversali riduttori, invece, possono diminuire o aumentare la portata. Può collegare tubi di dimensioni diverse. I raccordi filettati contengono scanalature nelle aperture per facilitare l'installazione. I raccordi a croce a compressione utilizzano connettori a pressione per rendere la tubazione priva di perdite.

Le abitazioni, le fabbriche e le industrie utilizzano i connettori trasversali nelle loro tubazioni. Incanalano il flusso di aria e gas nei sistemi HVAC. Sono utilizzati anche nei canali di irrigazione e nella gestione delle acque reflue.

Gomito

Il raccordo a gomito è un componente delle tubazioni che collega due condotte. Viene utilizzato per deviare il flusso a diverse angolazioni. Il raccordo a gomito presenta due aperture filettate maschio. Può anche essere formato utilizzando un raccordo a T e bloccando un'apertura.

Un raccordo a gomito può essere classificato in base alla sua angolazione. Il raccordo a 90 gradi collega due tubi ad angolo retto. Il raccordo a gomito a 45 gradi può collegare due tubi ad angolo con un angolo ancora più acuto. Esiste anche il gomito a 180 gradi, che può deviare il flusso all'indietro.

I giunti a gomito sono ampiamente utilizzati in impianti idraulici, HVAC, edilizia, impianti chimici e installazioni marine. I materiali più comuni utilizzati per la realizzazione dei giunti a gomito sono l'acciaio inox, l'acciaio al carbonio, le leghe speciali, ecc.

Accoppiamento

Il giunto è uno strumento per tubazioni che collega due tubi. È disponibile in vari tipi: filettato femmina, filettato maschio o una combinazione. Viene utilizzato per adattare il flusso di liquidi o gas, allungare la rete di tubazioni o terminare un percorso.

Il giunto completo è un tipo di giunto per tubi che collega tubi di diametro simile. Esistono anche i mezzi giunti, che collegano due giunti tra loro. I giunti riduttori sono un altro tipo di giunti utilizzati per ridurre il flusso dell'acqua. Collegano un tubo più grande a un tubo più piccolo.

I connettori di accoppiamento sono ampiamente utilizzati negli impianti di riscaldamento e condizionamento. Sono utilizzati anche nelle reti di tubazioni dei generatori di energia e degli impianti marini. I materiali più comuni utilizzati per la realizzazione dei giunti sono l'acciaio inossidabile, l'acciaio zincato e l'acciaio all'ossido nero.

Adattatori

Gli adattatori sono componenti di tubazioni che collegano diversi tipi di tubi. Ad esempio, un adattatore può contenere un raccordo a compressione a un'estremità e un raccordo filettato all'altra. Gli adattatori per tubi sono realizzati con connettori maschi e femmine.

Gli adattatori presentano un'ampia gamma di forme di apertura. Gli adattatori filettati sono facili da installare. È possibile collegare i tubi ruotandoli insieme. Gli adattatori a compressione si chiudono strettamente intorno al tubo per fissare le giunzioni. Per una maggiore sicurezza, si può scegliere un adattatore a spine. Sono dotati di barbe che si fissano alle aperture dei tubi. Sul mercato sono disponibili diversi altri tipi di adattatori specializzati.

Gli adattatori in ottone resistono all'ossidazione e alla ruggine e sono quindi ideali per l'irrigazione. Gli adattatori in acciaio inox possono sopportare flussi di gas ad alta pressione. Gli adattatori in rame e PVC sono adatti per le tubature grazie alla loro resistenza alla corrosione, alla conducibilità termica e al prezzo.

Boccola

A volte è necessario collegare tubi con connettori diversi. Questo può accadere spesso quando si ristrutturano vecchie reti di tubazioni. I giunti a boccola possono collegare tubi di tipo diverso, ad esempio maschio-femmina o filettati-saldati. Possono collegare tubi di dimensioni e aperture diverse. Possono essere dotati di filettatura interna o esterna.

I materiali più comuni per i connettori a boccola sono plastica, acciaio, ottone e bronzo. Sono eccellenti per uso generale, industria chimica, idraulica e oleodotti.

Sindacati

I raccordi per tubi facilitano il compito di collegare e scollegare i tubi. Contengono estremità filettate e un dado di fissaggio. I tubi possono essere scollegati senza tagliare allentando il dado. Svolgono un ruolo fondamentale nei luoghi in cui è necessaria una regolare manutenzione e rimozione dei tubi.

Le valvole utilizzano dei raccordi. Sono disponibili nelle varianti a singolo e doppio bocchettone. Le valvole a bocchettone singolo consentono di scollegare il tubo da un'estremità. Le valvole a doppio raccordo consentono di rimuovere l'intero corpo della valvola.

Apparecchiature come pompe, valvole di pressione e misuratori di portata utilizzano i raccordi. Possono anche essere montati all'inizio o alla fine di una bobina di tubo. Sono utili nelle reti di tubazioni che richiedono installazioni e rimozioni regolari.

Capezzolo

I raccordi Nipple sono filettati maschio su entrambe le estremità. Possono collegare due tubi con filettatura femmina. Sono spesso utilizzati nel settore idraulico grazie alla loro efficiente struttura a dado e bullone. Gli idraulici possono lavorare facilmente con una chiave inglese.

I nippli ravvicinati presentano uno spazio non filettato minimo o nullo tra le aperture. Al contrario, i nippli a barile presentano un lungo spazio non filettato tra le aperture. Un nipplo a saldare ha una parte non filettata che può essere fissata all'apertura del tubo.

I giunti a nipplo sono componenti utili nell'industria idraulica, petrolifera, del gas e petrolchimica.

Trappola

I raccordi a trappola sono connettori a forma di "U" o "P" utilizzati per collegare un lavandino, una vasca da bagno o un bacino al canale di drenaggio. Funzionano intrappolando parte dell'acqua in una depressione che crea una barriera per i gas di scarico. I raccordi a trappola impediscono il riflusso dei gas di fogna nell'abitazione e la diffusione di cattivi odori.

Il tipo di collegamento più comune è il sifone a "P" o a "U". Collega il lavabo al canale di drenaggio attraverso la parete. Il sifone a "S" è un raccordo simile che collega il lavandino al canale di drenaggio attraverso il pavimento. Il sifone a bottiglia è un altro tipo di raccordo che consiste in un contenitore simile a una bottiglia che immagazzina l'acqua.

Flangia

I connettori a flangia sono raccordi per tubi per impieghi gravosi. Sono costituiti da flange che vengono fissate al tubo mediante bulloni o guarnizioni. Si trovano in una varietà di applicazioni come tubazioni industriali, oleodotti e gasdotti, scarichi di servizi igienici, ecc.

I raccordi flangiati sono di vari tipi: gomiti, raccordi a T, riduzioni, croci, adattatori e valvole. Se si lavora con una tubazione ad alta pressione, è probabile che si vedano raccordi flangiati. Vengono utilizzati anche nelle tubazioni sotterranee e nei percorsi a lunga distanza.

Cappello

Come la parola stessa, i connettori a cappuccio sono componenti per tubazioni che si inseriscono all'estremità del tubo. Hanno un'unica apertura. Vengono utilizzati per sigillare un tubo e impedire la fuoriuscita di liquido. I connettori a cappuccio sono necessari per terminare le tubazioni o per fornire un'interruzione temporanea per la manutenzione delle tubazioni.

I tappi in plastica, gomma, metallo o PVC sono i più utilizzati. Forniscono una tenuta ermetica alla tubazione e prevengono le perdite. Le applicazioni più comuni dei raccordi a cappuccio sono l'idraulica, l'HVAC, le fabbriche e l'agricoltura.

Spina

I raccordi a innesto hanno la stessa funzione dei raccordi a tappo. Bloccano l'apertura di un tubo e impediscono la fuoriuscita del fluido. Invece di essere montati sopra l'apertura, i tappi si inseriscono nel tubo. Sono connettori maschi.

Un altro modo in cui i tappi per tubi funzionano è quello di chiudere le aperture in alcune parti del tubo. Possono anche chiudere le aperture nelle pareti e in altri punti in cui un tappo non può essere utilizzato. È necessario adattare il materiale e le dimensioni del tappo al tubo.

Valvole

Le valvole sono particolari tipi di raccordi per tubi progettati per controllare il flusso del liquido nel tubo. Sono costituite da due aperture e da una barriera che limita il flusso del tubo. Questa barriera può essere controllata ruotando la valvola. Quando è necessario un controllo preciso del volume del liquido, le valvole sono estremamente utili.

Le valvole a campana sono costituite da una leva a un quarto di giro fissata sul tubo. Quando la leva è parallela alla tubatura, l'acqua scorre senza ostacoli. Tuttavia, quando la leva è perpendicolare, l'acqua smette di scorrere. La valvola a saracinesca ha un funzionamento simile a quello della valvola a campana, ma utilizza un cancello per bloccare il flusso dell'acqua. Le valvole a globo utilizzano ruote per azionare un otturatore nella valvola. Possono gestire il volume del liquido con grande precisione.

Per la loro precisione, le valvole sono un componente fondamentale di impianti chimici, fabbriche idrauliche, generatori pneumatici, ecc.

Metodi di connessione

Raccordi a pressione

I raccordi push-to-connect sono i vostri migliori amici se state lavorando a un progetto fai-da-te. Sono costituiti da un anello femmina e da un inserto maschio. Collegando i due elementi, è possibile unire facilmente i tubi. Sono ideali per le applicazioni a bassa pressione.

Raccordi filettati

I connettori filettati sono costituiti da scanalature interne o esterne. Per i connettori maschi, le scanalature si trovano all'interno. Per i connettori femmina, le scanalature si trovano all'esterno. L'esempio migliore per capire questo aspetto è quello di una bottiglia con un coperchio twist-off. Il tappo è femmina e l'apertura della bottiglia è maschio. Utilizzando i raccordi filettati, è possibile collegare i tubi attorcigliandoli tra loro.

Raccordi a sudare

Un raccordo a sudore è un collegamento permanente per tubi. Il tubo e il connettore sono saldati insieme, un processo noto come "sudorazione". È un elemento fondamentale dei raccordi per tubi in ottone e rame.

Raccordi a scorrimento

Questi tipi di raccordi sono realizzati in plastica o PVC. Hanno pareti lisce e senza scanalature. Vengono fissati insieme con una miscela di primer e cemento.

Raccordi a compressione

Questi raccordi sono stretti, sicuri e compatti. Il raccordo è fissato con una filettatura, un dado e un manicotto. I giunti a compressione sono altamente resistenti alle perdite.

Raccordi a flangia

I raccordi svasati sono connessioni altamente sicure realizzate con il processo di svasatura. Si tratta di un processo di formatura a freddo in cui il raccordo viene espanso e poi posizionato sul tubo. La connessione che si forma quando si comprime è stretta e sicura.

Raccordi a morsetto

Il morsetto è un componente esterno che viene fissato con dadi, bulloni o viti. Viene montato sul giunto e serrato per fissarlo.

Raccordi a crimpare

La crimpatura comprime un anello metallico sul giunto, formando una connessione stretta e sicura.

Quali sono i materiali utilizzati per i raccordi per tubi?

Siete stati sopraffatti dai tipi di materiali di cui sono fatti i raccordi per tubi? Noi lo capiamo. L'ottone e il rame sono le scelte giuste per i raccordi per tubi per impieghi gravosi. L'alluminio e il PVC, invece, sono economici e versatili. L'acciaio inox è la qualità più elevata, ma è costoso. Quindi, qual è il materiale migliore per voi?

I raccordi per tubi in alluminio sono leggeri, resistenti alla corrosione ed economici. Tuttavia, non sono adatti alle tubazioni ad alta pressione. I raccordi per tubi in rame e ottone sono resistenti e durevoli. Hanno buone prestazioni anche in condizioni di alta pressione e temperatura. Tuttavia, sono difficili da installare e soggetti a congelamento. I raccordi per tubi in PVC sono economici, facili da installare, non soggetti a corrosione e di lunga durata. Tuttavia, il calore rende i tubi di plastica suscettibili di deformarsi, rendendoli una scelta sbagliata per il trasporto di liquidi caldi.

La scelta del materiale per il raccordo dipende in larga misura dalla rete di tubazioni. Si raccomanda di utilizzare lo stesso materiale per i tubi. Esistono tuttavia delle eccezioni. Le norme sulle tubazioni consentono di utilizzare alcuni raccordi con materiali diversi. Ad esempio, i raccordi in ottone possono essere utilizzati con reti di tubi in rame. I raccordi devono essere in grado di gestire la pressione e la temperatura richieste dal resto della tubazione. Inoltre, devono essere adatti al liquido o al gas che trasportano.

Come scegliere il raccordo giusto

Materiale

La scelta del materiale dipende dal sistema di tubazioni e dal liquido/gas che esso trasporterà. Assicurarsi che il materiale dei raccordi sia conforme agli standard internazionali come ANSI, ASME, ISO e DIN.

Dimensioni

Le specifiche di dimensionamento sono fattori importanti da considerare prima di acquistare i raccordi per tubi. Assicurarsi che il produttore fornisca informazioni sulle dimensioni dei raccordi per tubi. Secondo il sistema inglese, la misura è in pollici. Nel sistema metrico, invece, la misurazione avviene in mm o cm. Il diametro interno del raccordo deve corrispondere al diametro interno della linea di collegamento. Allo stesso modo, la larghezza esterna del raccordo deve corrispondere alla larghezza esterna della linea di collegamento.

Tipi di filo

I tipi di filettatura possono avere un impatto significativo sul progetto. Determinano la pressione che i raccordi per tubi possono gestire. Esistono diversi tipi di filettatura per tubi. NPT è lo standard di filettatura più comune negli Stati Uniti. I tubi certificati ANSI utilizzano lo standard di filettatura NPT. Nel Regno Unito e in Europa è prevalente lo standard BSP. Altri tipi di filettatura sono NPTF e JIS.

Conclusione

I raccordi per tubi sono l'elemento più importante di qualsiasi progetto idraulico. Sia che stiate costruendo una rete idrica domestica o che stiate realizzando un sistema di drenaggio per un impianto chimico, utilizzerete una combinazione di raccordi per tubi diversi. A parte il gergo tecnico, la scelta di un raccordo è spesso una scelta personale. I diversi materiali hanno punti di forza e di debolezza differenti. Quando si costruiscono reti di tubazioni di grandi dimensioni, occorre tenere conto anche dei costi. Assicuratevi che la vostra condotta sia conforme agli standard adottati dagli enti pubblici. Per ulteriori informazioni sui raccordi per tubi e per una consulenza approfondita, contattate il nostro team di professionisti. Saremo lieti di aiutarvi a scegliere il raccordo perfetto per il vostro progetto.