Pabrik pipa ERW baja karbon

Pipa Baja ERW (Pipa Las Tahan Listrik), Pipa ERW Baja Karbon

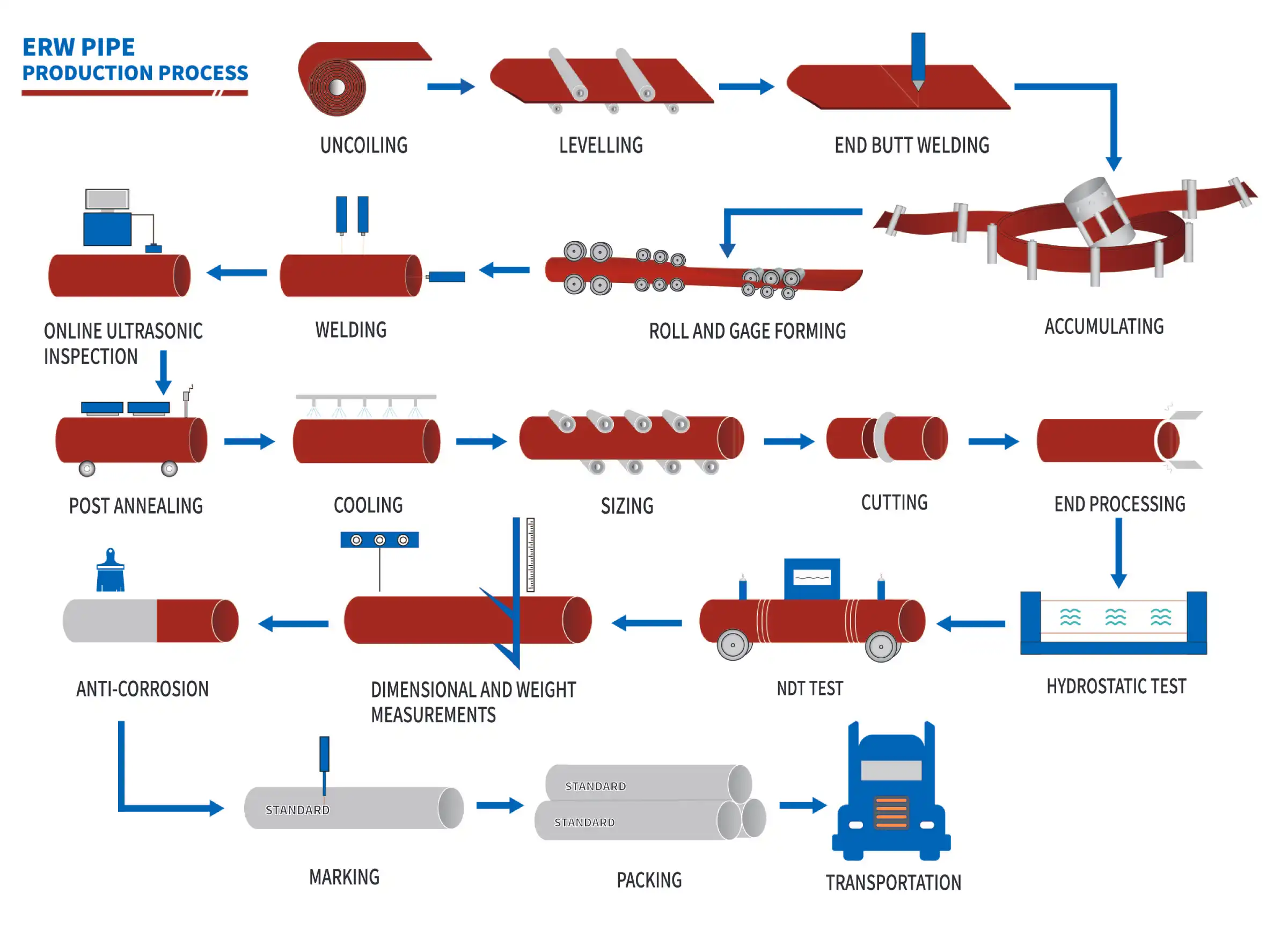

Pipa Electric Resistance Welded (ERW) terbuat dari gulungan baja karbon berkualitas tinggi, dibentuk dingin menjadi bentuk silinder dengan las longitudinal yang sejajar dengan pipa.

Uniasen adalah pemasok pipa ERW grosir terpercaya di Cina. Pipa ERW kami diproduksi menggunakan jalur pengelasan otomatis canggih dan tersedia dalam diameter hingga 24 inci (610 mm) untuk memenuhi kebutuhan industri yang berbeda. Lebar koil sesuai dengan keliling pipa, memastikan kinerja untuk pengangkutan minyak, gas, dan berbagai cairan atau uap.

Ukuran pipa kami berkisar dari 1/2 inci hingga 24 inci, cocok untuk pengelasan, penguliran, alur, dan pembengkokan, memberikan keserbagunaan untuk proyek-proyek di seluruh dunia