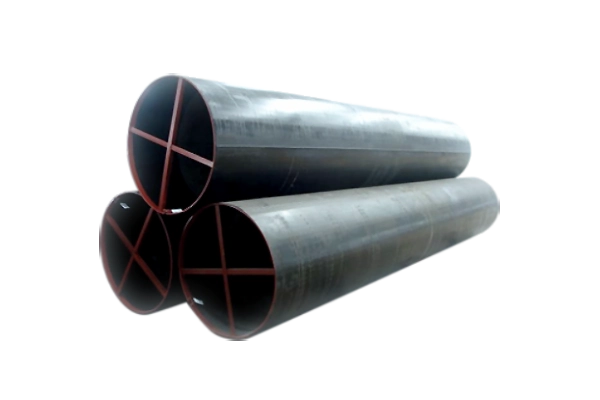

Fornecedor de tubos DIN 1626 na China

Visão geral padrão:

A norma DIN 1626 especifica os requisitos técnicos para tubos de aço soldados para aplicações de pressão.

Materiais principais:

Aços sem liga e de baixa liga, sendo St 37.0 e St 44.0 os tipos de aço mais comuns.

Aplicativos:

Os tubos de aço soldados conforme a norma DIN 1626 são amplamente utilizados em setores que precisam de controle de pressão estável. Isso inclui cadeias de suprimentos, plantas de processamento e tanques de armazenamento. Eles funcionam melhor em temperaturas e pressões baixas a médias.

Os tubos de aço soldados da UNIASEN seguem rigorosamente a norma DIN 1626. Isso garante alta confiabilidade e durabilidade para vários usos industriais.

Obter uma cotação gratuita