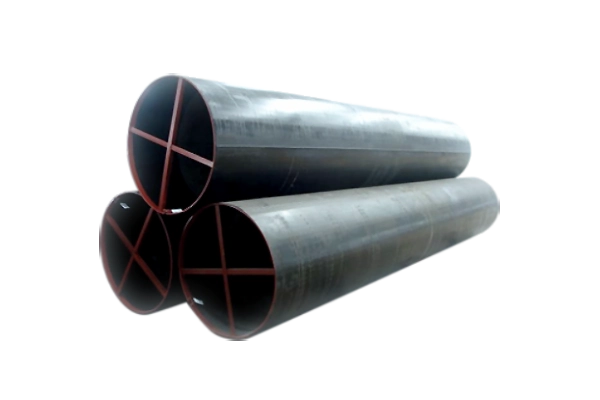

Pemasok Pipa DIN 1626 di Cina

Gambaran Umum Standar:

DIN 1626 menetapkan persyaratan teknis untuk pipa baja yang dilas untuk aplikasi tekanan.

Bahan utama:

Baja non-paduan dan paduan rendah, dengan St 37.0 dan St 44.0 adalah kelas baja yang paling umum.

Aplikasi:

Pipa baja yang dilas ke DIN 1626 banyak digunakan dalam industri yang membutuhkan kontrol tekanan yang stabil. Ini termasuk rantai pasokan, pabrik pengolahan, dan tangki penyimpanan. Pipa ini bekerja paling baik pada suhu dan tekanan rendah hingga sedang.

Pipa baja yang dilas UNIASEN secara ketat mengikuti DIN 1626. Hal ini memastikan keandalan dan daya tahan yang tinggi untuk berbagai penggunaan industri.

Dapatkan Penawaran Gratis