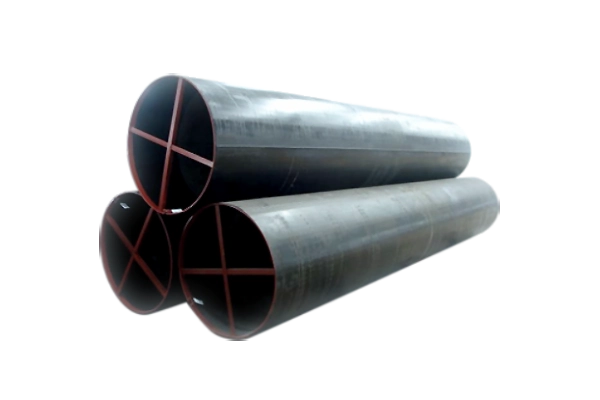

China Din17175 Kesselrohr Hersteller und Lieferant

Die DIN 17175 legt die technischen Anforderungen für nahtlose hitzebeständige Stahlrohre fest. Geeignet für Kessel, Hochdruckrohrleitungen und Hochtemperaturanlagen.

Sie umfasst eine Reihe von hitzebeständigen Stahlsorten (z. B. St 35.8, 15Mo3) und spezifiziert die chemische Zusammensetzung, die mechanischen Eigenschaften, die Abmessungen und die Beanspruchung bei hohen Temperaturen (bis 600 °C).

Diese Norm gewährleistet, dass Rohre auch unter rauen Bedingungen zuverlässig und sicher sind. Sie entspricht internationalen Normen wie der EN 10216.

Jetzt zitieren